When working with metal, selecting the right grinding wheel is essential for efficiency and achieving optimal results. A 7-inch grinding wheel is a versatile tool that strikes a balance between size and performance, offering great control and durability for metalworking tasks. In this blog, we’ll explore the key aspects of 7-inch grinding wheels for metal, including their features, applications, and tips for selecting the best one.

Key Features of a 7-Inch Grinding Wheel for Metal

Material Composition

Grinding wheels for metal are typically made from materials like aluminum oxide, zirconia alumina, or ceramic grain. These materials provide the hardness and durability needed to grind metals effectively, ensuring a smooth finish and long-lasting performance.

Bond Type

The bond holds the abrasive particles together and determines the wheel’s hardness. For metal grinding, a harder bond is preferable to handle the toughness of steel and other alloys. Resin-bonded wheels are commonly used because they offer flexibility and resilience.

Grit Size

The grit size affects the surface finish and grinding speed. Coarser grits (16-24) are used for heavy material removal, while finer grits (36-60) are used for smoothing or finishing work. Depending on your project needs, the right grit size will ensure efficient grinding.

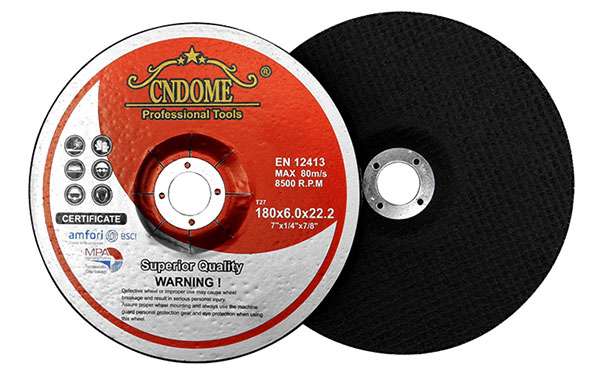

RPM Rating

A 7-inch wheel typically works with angle grinders rated for 8,500 RPM. It’s crucial to ensure that the wheel’s RPM rating matches your tool’s capabilities for safety and performance.

Applications of a 7-Inch Grinding Wheel for Metal

Material Removal

Whether you’re working on mild steel, stainless steel, or hardened alloys, a 7-inch grinding wheel can efficiently remove large amounts of material. It’s ideal for heavy-duty grinding tasks like smoothing welds, removing rust, or cutting off excess metal.

Beveling and Edge Work

These wheels are often used for beveling metal surfaces before welding. A 7-inch wheel offers better control for creating clean, angled edges that improve weld quality and joint strength.

Surface Preparation

Grinding wheels are perfect for preparing metal surfaces before painting or coating. The 7-inch size allows for fast coverage while maintaining precision in tight areas, ensuring an even surface free of burrs and imperfections.

Weld Cleaning

After welding, 7-inch grinding wheels can be used to clean weld seams and joints. The wheel removes slag and smooths out rough welds, providing a polished finish that is both functional and aesthetically pleasing.

Tips for Choosing the Best 7-Inch Grinding Wheel for Metal

Match the Wheel to the Metal Type

The type of metal you’re grinding plays a significant role in wheel selection. Aluminum oxide wheels are ideal for general-purpose grinding, while zirconia or ceramic wheels are recommended for tougher metals like stainless steel.

Consider Wheel Hardness

For hard metals, a softer grinding wheel may wear out faster but will provide better performance in terms of cutting speed. Conversely, for softer metals, a harder wheel will last longer and maintain its sharpness.

Opt for Reinforced Wheels

Reinforced grinding wheels contain fiberglass mesh layers, which increase the strength of the wheel, making them safer and more durable when used on tough metals. Always ensure your wheel is reinforced for enhanced safety, especially during heavy-duty grinding.

Use a Proper Flange System

Make sure your angle grinder has the right flange system to securely hold the 7-inch grinding wheel in place. An improper setup can lead to imbalanced grinding and potential safety hazards.

Safety Tips When Using 7-Inch Grinding Wheels

Wear Protective Gear

Always wear safety goggles, gloves, and hearing protection when grinding metal. Grinding generates sparks, debris, and loud noise, so proper gear ensures safety.

Check Wheel Condition

Inspect the wheel for cracks, chips, or any damage before use. Damaged wheels can break apart during operation, posing a serious risk.

Ensure Proper Installation

Confirm that the wheel is properly mounted and aligned on the grinder. An incorrectly installed wheel can cause excessive vibrations, reducing precision and increasing the risk of accidents.

Follow the RPM Limits

Exceeding the recommended RPM for a grinding wheel can cause it to break or overheat. Always verify that your grinder’s speed is within the limits of the wheel’s rating.

Conclusion

The 7-inch grinding wheels for metal is an essential tool for both professional metalworkers and DIY enthusiasts. It offers the right balance of power, control, and versatility to handle a range of metal grinding tasks. By selecting the appropriate wheel material, grit size, and ensuring proper usage, you can maximize your grinding efficiency and achieve high-quality results on every project.

Whether you’re cleaning up welds, removing rust, or preparing surfaces for further work, a 7-inch grinding wheel is a must-have in your toolbox.