Bench grinders are versatile and essential tools in many workshops, garages, and DIY projects. One crucial component of these powerful machines is the grinding wheel. Bench grinder wheels come in various types and sizes, each designed to perform specific tasks. In this blog post, we will explore the different types of bench grinder wheels, their uses, and essential maintenance tips to ensure optimal performance and safety.

I. Types of Bench Grinder Wheels:

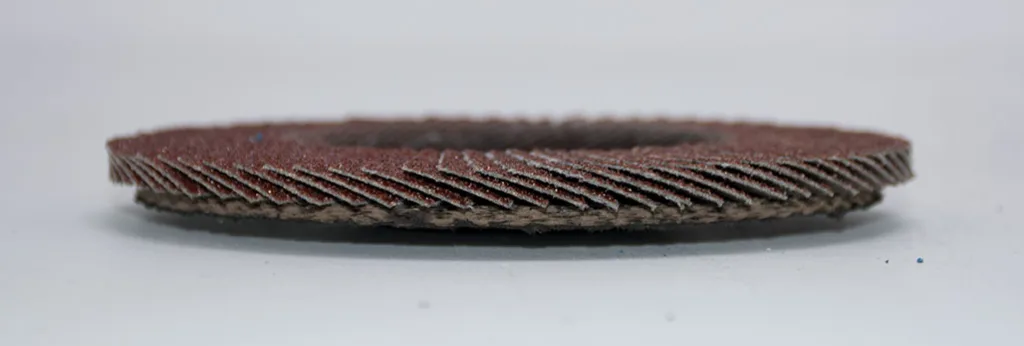

Aluminum Oxide Wheels:

Most common type used for general-purpose grinding.

Suitable for grinding ferrous metals, such as steel and iron.

Available in various grits for different levels of aggressiveness.

Silicon Carbide Wheels:

Ideal for grinding non-ferrous metals like brass, aluminum, and copper.

Can also be used for sharpening tungsten carbide tools.

Known for their hardness and ability to retain sharpness.

Diamond Wheels:

Utilized for grinding extremely hard materials like carbides, gemstones, and ceramics.

Offer excellent precision and durability.

Frequently used in tool and die making, lapidary work, and glass grinding.

CBN (Cubic Boron Nitride) Wheels:

Similar to diamond wheels, but specifically designed for grinding high-speed steels and other hardened materials.

Provide superior heat resistance and longer lifespan compared to conventional wheels.

Widely used in the sharpening of woodworking tools and high-speed steel lathe tools.

II. Uses of Bench Grinder Wheel:

Grinding and Sharpening:

Bench grinder wheels are primarily used for grinding and sharpening various tools, such as chisels, axes, drill bits, and lawnmower blades.

They remove material and reshape the edges, restoring sharpness and efficiency.

Shaping and Deburring:

Bench grinder wheels are excellent for shaping metal, rounding corners, and removing burrs from freshly cut or machined parts.

They help achieve precise contours and smooth finishes.

III. Bench Grinder Wheel Maintenance:

Wheel Dressing:

Regularly dress the grinding wheel to maintain its shape and effectiveness.

Use a wheel dresser or a dressing stone to remove debris, glazing, and unevenness from the surface.

Checking for Damage:

Inspect the grinding wheel for any cracks, chips, or signs of wear before each use.

Damaged wheels can cause accidents and should be replaced immediately.

Balancing the Wheel:

Imbalanced wheels can cause excessive vibrations and reduce grinding accuracy.

Use a wheel balancing tool to ensure the wheel runs smoothly.

Proper Storage:

Store bench grinder wheel in a cool, dry place away from moisture and extreme temperatures.

Avoid stacking heavy objects on top of the wheels to prevent deformation.

Bench grinder wheels are indispensable tools for a wide range of grinding, sharpening, and shaping tasks. Understanding the different types of wheels available, their specific uses, and proper maintenance techniques is crucial for achieving optimal results and ensuring safety. By following the tips mentioned in this guide, you’ll be able to make the most out of your bench grinder wheels and extend their lifespan while enjoying accurate and efficient grinding operations.