Small angle grinders are versatile and powerful tools commonly used in metalworking, construction, and DIY projects. One of the key components that significantly impact their performance is the cutting blade. Selecting the right cutting blade for your small angle grinder is crucial for achieving precise, efficient, and safe cuts. In this blog post, we will explore the various types of cutting blades suitable for small angle grinders and factors to consider when making your selection.

1. Metal-Cutting Discs:

- Ideal for: Cutting through metal, steel, and other ferrous materials.

- Features: Metal-cutting discs are specifically designed with abrasives suitable for cutting through tough metals. Look for discs labeled as “metal-cutting” or “metal grinding” for optimal performance.

2. Diamond Blades:

- Ideal for: Cutting through hard materials like concrete, tiles, and masonry.

- Features: Diamond blades have embedded diamond particles that make them highly effective for cutting through hard materials. They are a popular choice for construction and renovation projects.

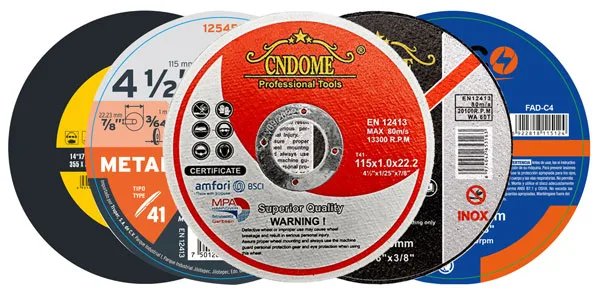

3. Abrasive Cutoff Wheels:

- Ideal for: General-purpose cutting in various materials.

- Features: Abrasive cutoff wheels are versatile and suitable for cutting through a wide range of materials, including metal, plastic, and wood. They are an excellent choice for DIY enthusiasts with diverse projects.

4. Masonry Blades:

- Ideal for: Cutting through bricks, blocks, and other masonry materials.

- Features: Masonry blades have a design optimized for cutting through abrasive and dense materials commonly found in construction. They can be used for both wet and dry cutting applications.

5. Wood-Cutting Blades:

- Ideal for: Precision cuts in wood and other soft materials.

- Features: Wood-cutting blades for small angle grinders typically have a higher tooth count, allowing for smoother and cleaner cuts in wood. They are essential for carpentry and woodworking projects.

Factors to Consider When Choosing Cutting Blades:

1. Material Compatibility:

Consider the type of material you’ll be cutting and choose a blade specifically designed for that material.

2. Blade Size:

Ensure that the blade size matches the specifications of your small angle grinder. Using the correct size is essential for safety and optimal performance.

3. Tooth Count and Design:

Different materials require different tooth designs. Select a blade with the appropriate tooth count for the material you are cutting.

4. Wet or Dry Cutting:

Some blades are suitable for wet cutting, which helps to reduce dust and increase blade longevity. Consider your working environment and choose accordingly.

5. Quality and Durability:

Invest in high-quality blades to ensure durability and longevity. Cheaper, inferior blades may wear out quickly and compromise the quality of your cuts.

Conclusion:

Choosing the right cutting blade for your small angle grinder is a critical decision that directly impacts the success of your cutting tasks. By considering the material, blade type, and other factors mentioned in this guide, you can make informed decisions and achieve precise and efficient cuts in your projects. Always prioritize safety by following manufacturer guidelines and wearing appropriate protective gear during cutting operations.