Cutting discs play an essential role in various industries, from metalworking and construction to automotive repair and DIY projects. Whether you’re a professional in need of heavy-duty tools or a hobbyist working on a smaller project, selecting the right cutting disc manufacturer is crucial to ensuring that you get a product that combines quality, durability, and performance.

1. Understanding the Importance of Cutting Disc Quality

The quality of a cutting disc directly impacts its effectiveness, efficiency, and safety. A poorly manufactured disc may wear out quickly, overheat, or even break during use, leading to safety hazards or poor results. High-quality cutting discs, on the other hand, offer precise cutting, extended service life, and smoother operation. When looking for a manufacturer, ensure they adhere to industry standards for quality control and use premium materials that stand up to rigorous cutting tasks.

2. Key Factors to Consider When Choosing a Cutting Disc Manufacturer

- Material Expertise: Cutting discs come in a variety of materials depending on the type of cutting required—whether it’s for stainless steel, metal, concrete, or even tiles. A manufacturer with expertise in producing discs for specific materials can offer more tailored solutions. Be sure to select a manufacturer that specializes in the materials you’re working with to ensure optimal performance.

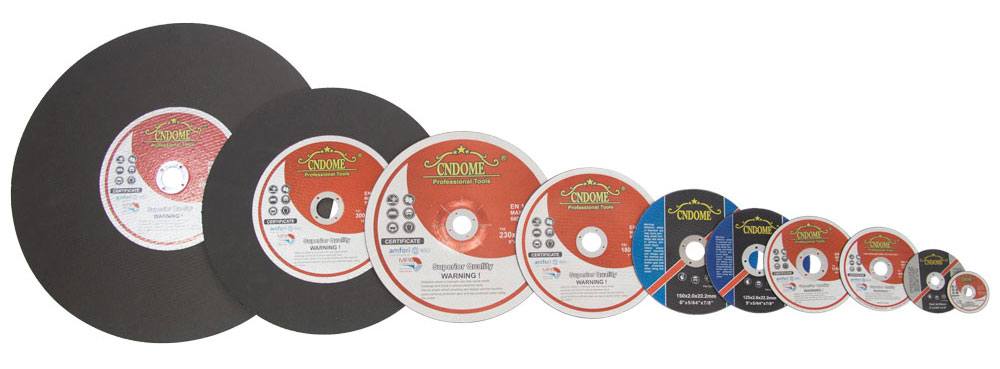

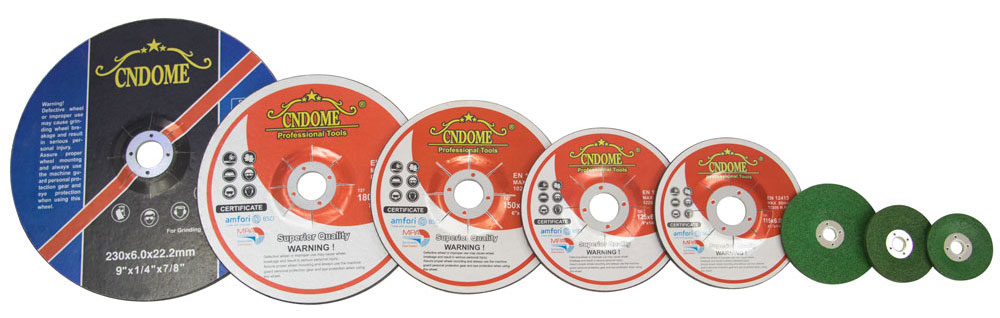

- Range of Products: The best cutting disc manufacturers provide a wide range of options to suit different applications. Whether you’re looking for thin discs for precision cuts, thicker discs for heavier-duty tasks, or discs with specialized abrasives, variety is key. A good manufacturer will understand the nuances of different cuts, offering tailored products for each need.

- Innovative Features: Technology and innovation play a huge role in improving cutting disc performance. Look for manufacturers that offer discs with advanced features, such as reduced noise, less vibration, longer service life, and faster cutting speeds. Some manufacturers invest in research and development to create proprietary features that provide a competitive edge.

- Certifications and Compliance: Always check for certifications such as ISO 9001, ANSI, or other industry-specific standards. These certifications ensure that the manufacturer complies with stringent quality control measures and produces cutting discs that are safe, durable, and reliable.

3. Manufacturing Process and Materials Used

Cutting discs are typically made from abrasive materials like aluminum oxide, zirconia, silicon carbide, and diamond, all of which offer varying levels of toughness and performance. The manufacturing process can differ, with some companies using advanced methods such as resin bonding or metal core bonding to ensure the discs are strong and wear-resistant.

- Abrasive Material: The material used for the disc’s abrasives determines the cutting performance. For example, aluminum oxide discs are commonly used for general-purpose metal cutting, while zirconia abrasives are better suited for harder materials like stainless steel.

- Bonding Material: The bonding material is responsible for holding the abrasives together. Different bond types (resin, metal, ceramic) impact the disc’s flexibility, wear rate, and overall performance.

4. Safety Features and Compliance

Safety should always be a top priority when selecting a cutting disc. A reputable manufacturer will design products that adhere to international safety standards and include features that minimize risks during operation. Look for discs that are reinforced with fiberglass for added strength, especially for those used in high-speed cutting applications. Additionally, manufacturers should provide clear safety guidelines on proper usage and maintenance of the discs.

5. Reputation and Customer Reviews

One of the best ways to gauge the reliability of a cutting disc manufacturer is by examining customer reviews and testimonials. Positive feedback from businesses and end-users speaks volumes about the manufacturer’s consistency, reliability, and overall product satisfaction. Don’t hesitate to ask for recommendations from industry peers or read up on online forums for firsthand experiences.

6. Cost and Value for Money

While it’s important to consider price, the most expensive disc isn’t always the best value. Look for a manufacturer that offers competitive prices without sacrificing quality. A manufacturer that offers bulk discounts or custom orders for specific projects may also provide better long-term value. Compare prices, warranties, and the expected lifespan of the products to make an informed decision.

7. Customer Support and Service

A good manufacturer will not only provide high-quality products but also offer excellent customer support. If you’re dealing with a large project or need a custom order, prompt communication, technical advice, and after-sales support can make all the difference. Look for manufacturers with a track record of responsive customer service.

8. Environmental Considerations

Sustainability is becoming a more important factor in manufacturing. Look for manufacturers who are committed to environmentally-friendly practices, such as minimizing waste, using recycled materials, or reducing carbon footprints. Discs made with sustainable processes are not only good for the environment but can also contribute to the growing demand for eco-conscious products.

Conclusion: Finding a Trusted Cutting Disc Manufacturer

Choosing the right cutting disc manufacturer is an investment in both safety and efficiency. By considering factors like material expertise, product range, quality certifications, and safety features, you can select a manufacturer that meets your needs and offers reliable, high-performance discs for your projects. Take the time to do thorough research and read reviews to find a supplier who aligns with your requirements and provides exceptional customer service.