Cut-off wheels are essential tools in metalworking, particularly when working with cast materials like cast iron, cast steel, or other alloys. These materials pose unique challenges due to their inherent properties such as hardness, brittleness, and often irregular structures. Choosing the right cut-off wheel for these applications ensures efficiency, safety, and high-quality results.

Understanding Cast Materials

What Are Cast Materials?

Cast materials are created by pouring molten metal into molds and allowing it to solidify. Common types include:

- Cast Iron: Known for its strength and durability, but highly brittle.

- Cast Steel: Offers higher ductility and toughness compared to cast iron.

- Other Alloys: Include various metals with specific properties tailored for industrial applications.

Challenges of Cutting Cast Materials

- Hardness and Brittleness: These properties make cutting more complex and increase the risk of wheel damage.

- Surface Imperfections: Cast materials often have irregular surfaces, requiring wheels that adapt to variable conditions.

- Heat Generation: Cutting can produce excessive heat, potentially compromising the material’s properties.

Features to Look for in Cut-Off Wheels for Cast Materials

Material Composition

Opt for wheels made with premium abrasives like:

- Aluminum Oxide: Excellent for general-purpose cutting of cast iron.

- Silicon Carbide: Ideal for harder materials, including cast steel and other alloys.

Bond Type

A resinoid bond ensures flexibility and strength, helping the wheel withstand the rigors of cutting cast materials.

Wheel Thickness

- Thin Wheels (1.0–1.6 mm): Provide precision cuts with minimal material loss, ideal for smaller sections.

- Thicker Wheels (2.5–3.2 mm): Offer durability and stability for heavy-duty applications.

Reinforcement

Wheels with double or triple reinforcement layers ensure safety and durability during high-speed operations.

Best Practices for Using Cut-Off Wheels on Cast Materials

Choose the Right Speed

Follow the manufacturer’s recommended RPM for your cut-off wheel. High speeds can cause overheating or wheel breakage.

Secure the Material

Ensure the cast material is securely clamped to prevent movement during cutting.

Coolant Use

Use coolants or water to manage heat and reduce wear on the wheel.

Proper Handling

Avoid applying excessive pressure; let the wheel do the work. Excessive force can lead to uneven cuts or wheel damage.

Inspect the Wheel

Regularly check for cracks or damage before use to maintain safety.

Applications of Cut-Off Wheels for Cast Materials

Cut-off wheels are widely used in industries such as:

- Automotive: Cutting engine blocks, manifolds, and brake components.

- Construction: Slicing through cast iron pipes or structural components.

- Manufacturing: Processing cast steel components for machinery or tools.

Top Picks for Cut-Off Wheels

When selecting cut-off wheels, consider these trusted options:

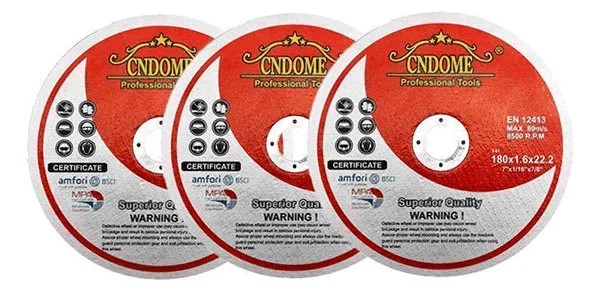

- CNDOME™ Cast Master Cut-Off Wheel: Designed for precision cutting of cast iron with minimal burrs.

- FlexPro Silicon Carbide Wheel: Excellent for hard alloys and high-strength cast steel.

- RapidCut Thin Wheel: Perfect for detailed cuts on intricate cast pieces.

Conclusion

Choosing the right cut-off wheel for cast materials can significantly impact your productivity and the quality of your work. By understanding the properties of cast materials, selecting the appropriate wheel, and following best practices, you can ensure efficient, precise, and safe cutting operations.

Explore our range of high-performance cut-off wheels to tackle your next project with confidence!