Metal cutting discs 230mm are essential tools for anyone involved in metalworking, from hobbyists to professional welders. Among the various sizes available, the 230mm metal cutting disc is a popular choice due to its versatility and efficiency. In this blog, we will delve into what makes the 230mm cutting disc special, its common uses, and tips for choosing the right disc for your project.

What is a 230mm Metal Cutting Disc?

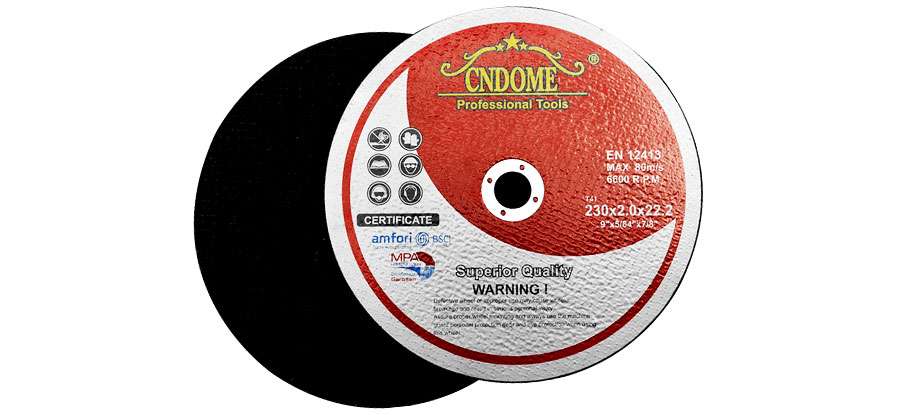

A 230mm metal cutting disc, also known as a cut-off wheel, is a type of abrasive disc designed specifically for cutting metal. It has a diameter of 230mm (approximately 9 inches), making it suitable for medium to heavy-duty cutting tasks. These discs are commonly used with angle grinders and are ideal for cutting through various types of metal, including steel, iron, and aluminum.

Key Features

- Size and Versatility: The 230mm diameter allows for deeper cuts compared to smaller discs, making it suitable for cutting thicker materials or making longer cuts in one pass.

- Material Composition: Typically made from aluminum oxide or zirconia alumina, these discs are designed to cut through metal efficiently while providing a smooth finish.

- Thickness: Metal cutting discs generally range from 1.6mm to 2.5mm in thickness. Thinner discs offer faster cutting speeds but may wear out more quickly, while thicker discs provide longer life and durability.

- Speed Rating: Ensure that the disc’s speed rating matches your angle grinder’s RPM (Revolutions Per Minute). Over-speeding can cause the disc to shatter, posing safety risks.

Common Uses

- Structural Steel Cutting: Perfect for cutting through structural steel beams, pipes, and plates. The 230mm disc’s size allows for cutting through larger materials without needing multiple passes.

- Automotive Repairs: Ideal for cutting exhaust pipes, chassis components, and other metal parts in automotive repair shops.

- Fabrication Work: Widely used in metal fabrication shops for creating custom metal parts, cutting through sheets, and trimming metal components to size.

- Demolition: In demolition work, these discs are used to cut through metal structures, rebar, and other metallic materials.

Tips for Choosing the Right 230mm Metal Cutting Disc

- Material Compatibility: Ensure the disc is rated for the specific type of metal you’re cutting. Discs designed for stainless steel, for example, may have different properties than those for cutting mild steel.

- Cutting Speed: Consider the cutting speed you require. Thinner discs cut faster but wear out more quickly, so choose based on the urgency and volume of your project.

- Durability: Look for discs that offer a balance between cutting speed and lifespan. Zirconia alumina discs tend to last longer, making them a good choice for heavy-duty applications.

- Safety: Always wear appropriate safety gear, including eye protection, gloves, and hearing protection when using cutting discs. Check the disc for any signs of damage before use, and never exceed the maximum RPM rating.

Conclusion

The 230mm metal cutting discs is a powerful tool in the arsenal of any metalworker. Its large size, combined with the right material composition and thickness, allows for efficient and effective cutting across a range of applications. Whether you’re involved in structural work, automotive repairs, or metal fabrication, understanding the features and proper usage of these discs will help you achieve better results and maintain a safe working environment.