In the realm of metalworking, precision is paramount. From shaping intricate details to achieving smooth finishes, every task demands tools that deliver accuracy and efficiency. Among these tools, die grinders stand out for their versatility and precision, offering craftsmen the ability to perform intricate grinding, cutting, and polishing tasks with ease. And at the heart of every die grinder lies a crucial component: the grinding wheel. Let’s delve into the world of grinding wheels specifically designed for die grinders and explore their significance in achieving fine finishes and intricate details.

The Role of Die Grinders in Metalworking

Before we delve into grinding wheels, let’s first understand the significance of die grinders in metalworking. Die grinders are handheld power tools equipped with a rotating spindle, typically powered by compressed air or electricity. These versatile tools come with various attachments and accessories, making them ideal for a wide range of tasks, including grinding, deburring, polishing, and engraving.

Die grinders are prized for their compact size, allowing craftsmen to access tight spaces and perform detailed work with precision. They are commonly used in industries such as automotive, aerospace, and manufacturing, where precision and fine finishes are paramount.

Grinding Wheels for Die Grinders: Precision in Every Grit

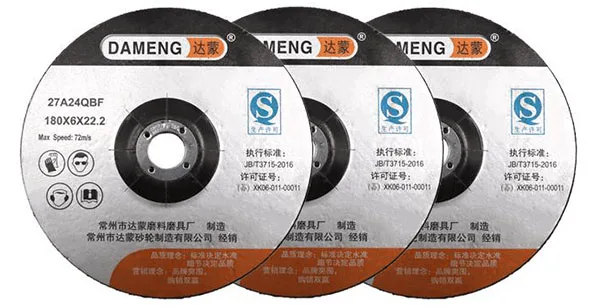

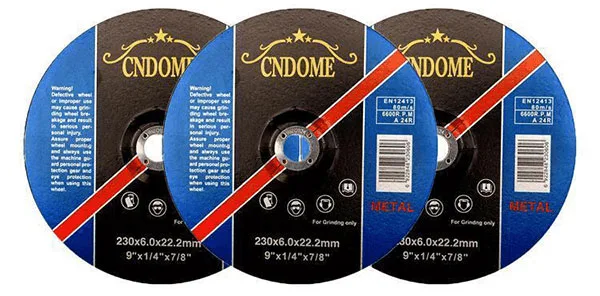

At the core of every die grinder lies its grinding wheel, a critical component that determines the tool’s performance and versatility. Grinding wheels for die grinders come in a variety of shapes, sizes, and compositions, each tailored to specific applications and materials.

- Abrasive Material: Grinding wheels for die grinders are typically made of abrasive materials such as aluminum oxide, silicon carbide, or diamond. The choice of abrasive material depends on the hardness of the workpiece material and the desired finish.

- Grit Size: The grit size of the grinding wheel determines its aggressiveness and the quality of the finish. Coarse grit wheels are suitable for rapid material removal, while finer grit wheels are ideal for achieving smooth finishes and intricate details.

- Wheel Shapes: Die grinder grinding wheels come in various shapes, including cylindrical, conical, and disc-shaped. Each shape offers unique advantages, allowing craftsmen to access different contours and perform specific tasks with precision.

Applications of Die Grinder Grinding Wheels

Die grinder grinding wheels find applications across a wide range of industries and tasks, including:

- Deburring: Removing sharp edges and burrs from metal components to ensure safety and functionality.

- Grinding: Shaping and smoothing metal surfaces to achieve precise dimensions and surface finishes.

- Polishing: Enhancing the aesthetic appeal of metalwork by achieving mirror-like finishes on surfaces.

- Engraving: Creating intricate designs and patterns on metal surfaces for decorative or functional purposes.

Conclusion

In the world of metalworking, where precision and finesse are non-negotiable, die grinders equipped with high-quality grinding wheels reign supreme. These versatile tools empower craftsmen to achieve fine finishes, intricate details, and precise dimensions with ease. Whether deburring sharp edges, shaping metal components, or polishing intricate surfaces, die grinder grinding wheels play a pivotal role in achieving excellence in metalwork. So, the next time you embark on a metalworking project that demands precision and finesse, trust in the power of die grinders and their precision grinding wheels to bring your vision to life.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address