Grinding wheels are essential tools in various industries, from metalworking to woodworking and beyond. They come in a myriad of sizes, each serving a specific purpose. Understanding the different sizes and their applications is crucial for achieving optimal results in your grinding tasks. In this blog post, we’ll delve into some of the popular sizes of grinding wheels and their respective uses.

1. Understanding Grinding Wheel Sizes:

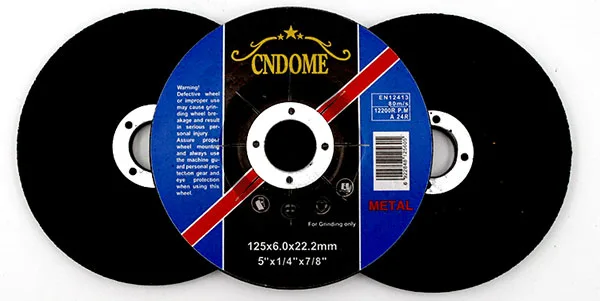

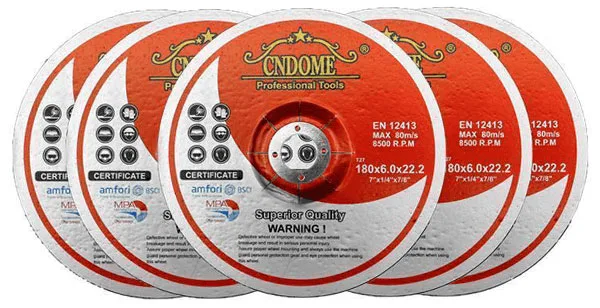

Grinding wheels come in a variety of sizes, each suited for specific tasks and machinery. The size of a grinding wheel is determined by its diameter and thickness, measured in inches or millimeters. For example, a common size might be 6 inches in diameter with a thickness of 1 inch.

2. Popular Sizes and Their Applications:

a. 4-Inch Grinding Wheels:

- These smaller wheels are commonly used in handheld angle grinders for tasks such as cutting, grinding, and polishing metal, stone, and other materials.

- They are ideal for precision work and detail-oriented projects due to their smaller size and maneuverability.

- Applications include metal fabrication, automotive repair, and DIY projects.

b. 6-Inch Grinding Wheels:

- Widely used in bench grinders, these wheels are versatile and suitable for various grinding applications.

- They offer a balance between size and surface area, making them effective for both heavy-duty material removal and finer finishing tasks.

- Applications include sharpening tools, shaping metal, and removing burrs.

c. 8-Inch Grinding Wheels:

- Larger and more robust, 8-inch grinding wheels are commonly found in industrial settings and workshops.

- They provide greater surface area and stability, allowing for efficient material removal and prolonged use without frequent dressing.

- Applications include heavy-duty grinding, sharpening large tools, and shaping hardened steel.

Factors to Consider When Choosing Grinding Wheel Sizes:

- Material Type: Different materials require specific grinding wheel sizes and compositions for optimal results. For example, softer metals may benefit from finer grit and smaller wheels, while harder materials necessitate larger wheels with coarser grit.

- Machine Compatibility: Ensure that the chosen grinding wheel size is compatible with the machinery being used, considering factors such as spindle size, horsepower, and safety requirements.

- Task Requirements: Assess the task at hand, including the desired finish, material removal rate, and precision level, to select the most appropriate grinding wheel size and specifications.

Conclusion:

Grinding wheels play a vital role in various industries, offering precise shaping, sharpening, and finishing capabilities. By understanding the popular sizes of grinding wheels and their applications, users can make informed decisions when selecting the right tool for their specific needs. Whether it’s a small 4-inch wheel for intricate detail work or a robust 8-inch wheel for heavy-duty grinding, choosing the correct size ensures efficiency, safety, and quality results in grinding operations.