In the bustling world of fabrication and construction, where precision and efficiency are paramount, the die grinder stands out as a versatile and indispensable tool. Among its many accessories, cutting discs take center stage, offering craftsmen and artisans a reliable means to shape, trim, and carve various materials with finesse and accuracy. Let’s embark on a journey to uncover the significance of cutting discs for die grinders and their myriad applications.

The Die Grinder: A Precision Powerhouse

Before we delve into cutting discs, let’s take a moment to appreciate the die grinder itself. A compact yet powerful handheld tool, the die grinder operates at high speeds, making it ideal for intricate grinding, polishing, and cutting tasks. Its ergonomic design and maneuverability make it a favorite among craftsmen, mechanics, and DIY enthusiasts alike.

Enter the Cutting Disc

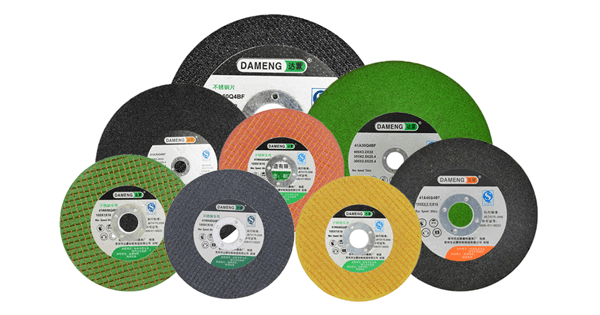

At the heart of many die grinder operations lies the cutting disc—a circular, flat disc typically made of abrasive materials such as aluminum oxide, silicon carbide, or diamond. These discs come in various diameters, thicknesses, and compositions, each tailored to specific cutting tasks and materials.

Applications Galore

The versatility of cutting discs knows no bounds, as they find applications across a spectrum of industries and tasks:

- Metal Fabrication: In metalworking, cutting discs are indispensable for slicing through sheet metal, rebar, bolts, and pipes with precision and ease. Whether it’s trimming excess material or creating intricate shapes, cutting discs deliver impeccable results.

- Construction and Masonry: From cutting tiles and bricks to shaping concrete and stone, cutting discs for die grinders are indispensable on construction sites. Their ability to make clean, accurate cuts enhances efficiency and craftsmanship in various building projects.

- Woodworking: Even in the realm of woodworking, cutting discs play a crucial role. Whether it’s trimming laminate flooring, carving intricate designs, or shaping wooden pieces, these discs offer woodworkers precision and control.

- Automotive Maintenance: Mechanics rely on cutting discs to trim metal panels, cut exhaust pipes, and perform other precision cutting tasks in automotive repair and maintenance. Their ability to navigate tight spaces makes them invaluable in cramped engine compartments.

- DIY Projects: Hobbyists and DIY enthusiasts also benefit from the versatility of cutting discs. Whether it’s crafting metal sculptures, building furniture, or renovating homes, these discs empower enthusiasts to bring their creative visions to life.

Safety First

While cutting discs offer unmatched precision and efficiency, it’s essential to prioritize safety when using them. Proper eye protection, gloves, and adherence to manufacturer guidelines are crucial to prevent accidents and injuries.

Conclusion

In the world of fabrication, construction, and craftsmanship, cutting discs for die grinders stand as indispensable tools, enabling artisans to shape, trim, and carve with unparalleled precision and efficiency. From metalworking to woodworking and everything in between, these discs empower craftsmen to turn their visions into reality, one precise cut at a time. So, the next time you reach for your die grinder and cutting disc, remember the boundless possibilities they offer in your quest for perfection.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address