Cutting discs are indispensable tools in a wide range of industries, from construction to metalworking and beyond. They are designed for precision cutting and, like any tool, their lifespan is determined by several factors. In this blog, we’ll delve into the key factors that influence how long you can use a cutting disc safely and effectively.

Understanding Cutting Disc Lifespan

The lifespan of a cutting disk primarily depends on several key factors:

Material Being Cut: The hardness and composition of the material you’re cutting play a significant role. Cutting through softer materials like wood or plastics is less abrasive on the disc compared to tough metals like steel or stainless steel.

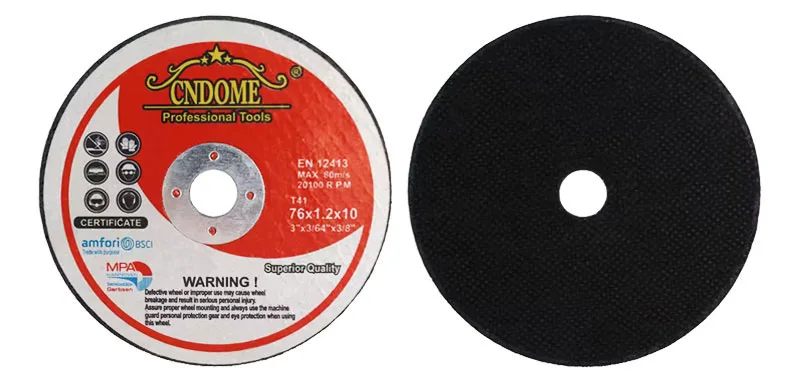

Disc Material and Quality: The type and quality of the cutting disc itself make a difference. High-quality discs with premium materials tend to last longer and offer better performance.

Workload and Pressure: Intense, prolonged use or excessive pressure on the cutting dis can wear it out more quickly. Using the right pressure and allowing the disc to do the work is essential for longevity.

RPM (Revolutions Per Minute): Exceeding the recommended RPM for your cutting disk can cause overheating and premature wear.

Proper Technique: Using the right technique, such as not twisting or binding the disc in the material, can significantly extend its lifespan.

Maintenance: Regular inspection and maintenance of your cutting disk, such as cleaning and sharpening, can prolong its life.

When to Replace a Cutting Disc

Knowing when to replace a cutting disc is vital for both safety and efficiency. Signs that it’s time for a replacement include:

Reduced Cutting Speed: If you notice the disc cutting more slowly than usual, it may be time for a new one.

Excessive Vibration: Increased vibration during operation can indicate a worn-out disc.

Wear and Tear: Physical damage, cracks, or visible wear on the disc are clear signs of replacement.

Decreased Precision: If your cuts are becoming less precise, it could be due to a dull or damaged disc.

Overheating: An excessively hot disc could indicate it’s struggling, and it’s time for a fresh one.

Tips to Extend the Life of Your Cutting Disc

While the lifespan of a cutting disc depends on various factors, you can maximize its utility through the following practices:

Use the Right Disc for the Job: Ensure you’re using a cutting disk suitable for the material you’re working on.

Maintain the Correct RPM: Always operate your tools at the recommended RPM to prevent overheating.

Work with Proper Technique: Use smooth, controlled movements and avoid forcing the disc through the material.

Regular Maintenance: Clean your cutting disk, inspect it for damage, and sharpen it if necessary.

Invest in Quality: High-quality cutting discs may cost more initially, but they often have a longer lifespan and offer better performance.

In conclusion, the lifespan of a cutting disc varies depending on several factors. By selecting the right disc for your job, using proper techniques, and practicing regular maintenance, you can significantly extend the life of your cutting tools. However, always keep an eye out for signs of wear and replace the disc when necessary to maintain safety and efficiency in your work.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address