Grinding wheels are essential tools used in various industries for material removal, shaping, and finishing processes. The speed at which a grinding wheel rotates, commonly referred to as RPM (revolutions per minute), plays a crucial role in achieving optimal results in terms of efficiency and safety. Understanding and appropriately managing grinding wheel RPM is essential for maximizing productivity and ensuring a safe working environment. In this blog post, we will explore the significance of grinding wheel RPM, its impact on performance, and how to determine and control the ideal RPM for different grinding applications.

Understanding Grinding Wheel RPM:

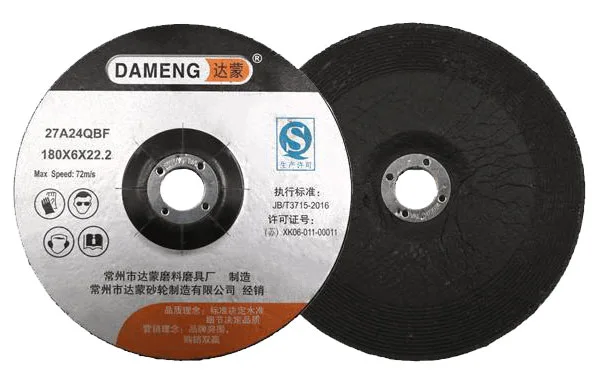

Grinding wheel RPM refers to the number of revolutions the wheel makes in one minute. It is a critical parameter that influences the cutting speed, material removal rate, surface finish, and overall grinding process. Operating a grinding wheel at an incorrect RPM can lead to various issues such as reduced performance, excessive heat generation, increased risk of wheel failure, and compromised operator safety.

Factors Affecting Grinding Wheel RPM:

Several factors should be considered when determining the appropriate RPM for a grinding wheel:

a. Wheel Diameter: Larger wheels typically require lower RPM, while smaller wheels can handle higher RPM. The wheel diameter affects the peripheral speed, and maintaining the recommended speed is crucial for wheel integrity.

b. Wheel Material: Different grinding wheel materials have varying speed limitations. For instance, vitrified bonds can withstand higher RPM compared to resin-bonded wheels. Manufacturers’ guidelines provide specific RPM limits for each wheel type.

c. Workpiece Material: The material being ground affects the choice of grinding wheel and, consequently, the optimal RPM. Harder materials may require slower RPM to prevent excessive heat generation and maintain wheel life.

Calculating the Ideal Grinding Wheel RPM:

To calculate the ideal RPM for a grinding wheel, you can use the following formula:

RPM = (SFM × 4) / (Wheel Diameter × π)

where RPM is the revolutions per minute, SFM (Surface Feet per Minute) is the desired cutting speed, and π is a mathematical constant (approximately 3.14).

It’s essential to consult the grinding wheel manufacturer’s guidelines and recommendations to ensure you are operating within the safe and efficient RPM range.

Safety Considerations:

Operating a grinding wheel at the appropriate RPM is crucial for maintaining a safe working environment. Here are some essential safety tips to keep in mind:

a. Never exceed the maximum RPM specified by the grinding wheel manufacturer.

b. Regularly inspect the grinding wheel for signs of damage or wear and replace it if necessary.

c. Use the appropriate personal protective equipment (PPE), such as safety glasses, face shields, and gloves, to protect against potential hazards.

d. Ensure that the machine’s guards are in place and properly adjusted to prevent wheel fragments from causing injury.

Mastering grinding wheel RPM is essential for achieving efficient and safe grinding operations. By understanding the factors that influence RPM and using the appropriate calculations, operators can optimize their grinding processes, enhance productivity, and prolong the life of grinding wheels. Remember to always follow the manufacturer’s guidelines, prioritize safety precautions, and regularly inspect and maintain the grinding equipment. With the right RPM and proper handling, grinding wheels can be powerful tools for precision and productivity in a wide range of industries.