When it comes to metalworking projects, having the right tools is crucial to achieving precise and efficient results. One such tool that plays a vital role in metal fabrication and finishing is the grinding disc. A good grinding disc can make a significant difference in terms of performance, durability, and overall quality of the workpiece. In this blog post, we will explore the key factors to consider when selecting the best grinding disc for metal, along with some top recommendations.

Material Composition:

The first consideration when choosing a grinding disc for metal is the material composition. Grinding discs are typically made from various abrasive materials, such as aluminum oxide, zirconia alumina, silicon carbide, or ceramic alumina. Each abrasive material has different characteristics, such as hardness, durability, and suitability for specific metals. For general-purpose metal grinding, aluminum oxide discs are commonly used due to their versatility and affordability.

Grit Size:

The grit size of a grinding disc determines its abrasive coarseness. Lower grit numbers indicate a coarser abrasive surface, which is suitable for heavy material removal and grinding rough surfaces. Higher grit numbers, on the other hand, produce a finer finish and are ideal for polishing and fine detail work. When selecting a grinding disc, consider the nature of your metalworking project to determine the appropriate grit size for achieving the desired results.

Disc Shape and Size:

Grinding discs come in various shapes and sizes, including flat discs, depressed center discs, and cutoff wheels. The choice of disc shape depends on the application and the type of grinder being used. For most metal grinding applications, flat discs or depressed center discs are commonly used. It is important to select the right disc size that matches your grinder’s specifications to ensure compatibility and safety.

Disc Durability:

Durability is a critical factor, especially when dealing with demanding metal grinding tasks. Look for grinding discs with reinforced construction, such as fiberglass mesh or resin bonding, which enhances their strength and longevity. High-quality discs are less likely to break or wear out quickly, resulting in longer tool life and reduced downtime.

Safety Features:

Working with grinding discs involves potential hazards, so prioritizing safety is essential. Opt for discs with safety features like reinforced outer guards or specially designed discs for reduced vibration and improved control. Always adhere to the manufacturer’s guidelines regarding safety precautions, such as using appropriate personal protective equipment (PPE) like safety glasses, gloves, and a face shield.

Top Recommendations:

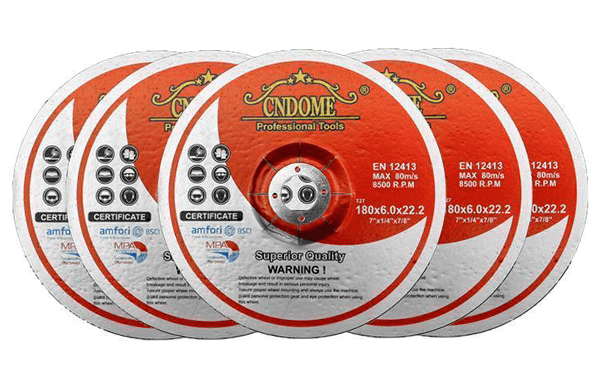

CNDOME 5 Inch Grinding Wheel

Material: Aluminum oxide

Grit Size: 24

Shape: Flat

Size: 5*7/8*1/4

Durability: Reinforced construction

CNDOME 7 Inch Grinding Wheel

Material: Aluminum oxide

Grit Size: 60

Shape: Depressed center

Size: 7*7/8*1/4

Durability: Reinforced with fiberglass mesh

Choosing the right grinding disc for metal is crucial for achieving optimal results in metalworking projects. Consider factors such as material composition, grit size, disc shape and size, durability, and safety features when making your selection. The recommended grinding discs mentioned above can serve as a starting point, but always ensure they meet your specific requirements.