Type 27 grinding wheels are among the most popular and versatile grinding tools used across various industries. Known for their durability, precision, and adaptability, these wheels are essential for professionals working with metal, concrete, and other tough materials. If you’re new to type 27 grinding wheels or looking to improve your work results, this guide will walk you through the key features, applications, and tips for selecting the right wheel for the job.

What is a Type 27 Grinding Wheel?

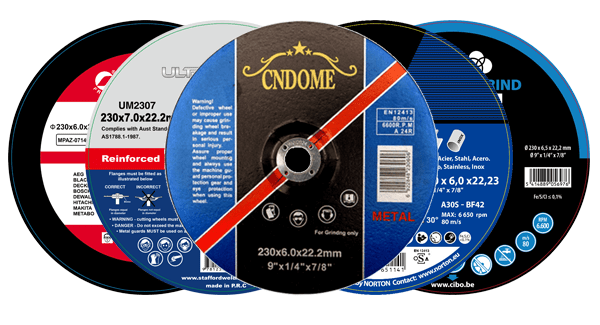

Type 27 wheels, also known as “depressed center” wheels, are designed with a unique shape that includes a central recess. This design gives them a slightly concave profile, which allows them to work at a more optimal angle for grinding and cutting applications. The angled construction improves control and reduces the likelihood of the wheel slipping, offering added safety and precision.

Key Features of Type 27 Grinding Wheels

- Depressed Center Design

The concave shape allows the user to grind at an optimal angle, generally 15 to 30 degrees, giving better control and minimizing surface contact. This design also allows the wheel to reach deeper areas, making it easier to grind in grooves and tight corners. - Wide Range of Abrasive Options

Type 27 grinding wheels come in various abrasive materials, including aluminum oxide, zirconia alumina, and ceramic. Each abrasive type is suited for specific applications—aluminum oxide is popular for general metal grinding, while ceramic abrasives are preferred for high-demand tasks. - Durable and Versatile

Made for heavy-duty work, Type 27 wheels are durable and long-lasting, suitable for grinding down welds, deburring, surface preparation, and even some forms of light cutting when necessary. - Compatibility with High-Speed Tools

These wheels are often compatible with high-speed angle grinders, which adds to their versatility in workshops, garages, and industrial settings.

Common Applications of Type 27 Grinding Wheels

Type 27 wheels are versatile, covering a range of applications across multiple industries:

- Metal Fabrication and Welding: Ideal for grinding weld seams, removing rust, and preparing surfaces for painting or coating.

- Construction: Used to smooth out rough edges on concrete, masonry, and stone.

- Automotive and Bodywork: Effective in smoothing down welds, removing old paint, and preparing surfaces for repair work.

- Manufacturing and Maintenance: Helpful in tool maintenance, shaping parts, and keeping machinery in top shape.

Selecting the Right Type 27 Grinding Wheel

When choosing a type 27 grinding wheel, consider the following factors to ensure you’re using the best wheel for your application:

- Material Compatibility

Choose the abrasive material based on the work material. For example:- Aluminum oxide is great for most metals, especially softer steels.

- Zirconia alumina is ideal for stainless steel and alloys.

- Ceramic abrasives work well with hardened metals and are useful for high-stress applications.

- Wheel Diameter and Thickness

Type 27 grinding wheels are available in different diameters, typically ranging from 4 to 9 inches, and thicknesses. Thicker wheels offer more durability for aggressive grinding, while thinner wheels are preferred for lighter, precision work. - Grit Size

Coarse grits (e.g., 24-36) remove material quickly and are suitable for heavy-duty tasks, while finer grits (60 and above) are ideal for finishing and polishing. - Operating Speed

Always check the maximum RPM rating of the wheel and match it to your angle grinder’s speed. Using a wheel above its rated speed can lead to breakage and accidents. - Bond Type

Type 27 wheels typically use resinoid bonds, which are designed to wear gradually, exposing fresh abrasive layers for effective grinding. Ensure the bond type suits the material hardness and the amount of material removal required.

Safety Tips for Using Type 27 Grinding Wheels

- Wear Safety Gear: Always wear goggles, gloves, ear protection, and appropriate workwear to protect against sparks, dust, and debris.

- Inspect the Wheel Before Use: Check for cracks, damage, or warping before mounting. A damaged wheel can break during use, causing injuries.

- Use Correct Mounting Techniques: Follow manufacturer instructions for mounting and always ensure the wheel is properly tightened.

- Maintain Optimal Grinding Angles: Type 27 wheels perform best when used at a 15-30 degree angle. Avoid excessive pressure, as it can cause overheating and uneven grinding.

Conclusion

Type 27 grinding wheels are a reliable and versatile tool for anyone involved in metalworking, construction, or maintenance. With various abrasive materials, sizes, and grit options, you can easily find the right wheel to meet your needs. By selecting the appropriate wheel and following safe usage practices, you’ll achieve smoother, faster, and more precise grinding results, enhancing both the efficiency and safety of your work.

Whether you’re a professional welder or a DIY enthusiast, adding a Type 27 grinding wheel to your toolkit is a smart investment for high-quality grinding and finishing tasks.