Type 27 Grinding wheel is essential tools in various industries, from metalworking to construction, providing the precision and durability needed for efficient grinding, deburring, and polishing tasks. Among the many types of grinding wheels, Type 27 grinding wheels are some of the most commonly used in the industry. These wheels are known for their versatility, safety features, and performance in a wide range of applications.

What is a Type 27 Grinding Wheel?

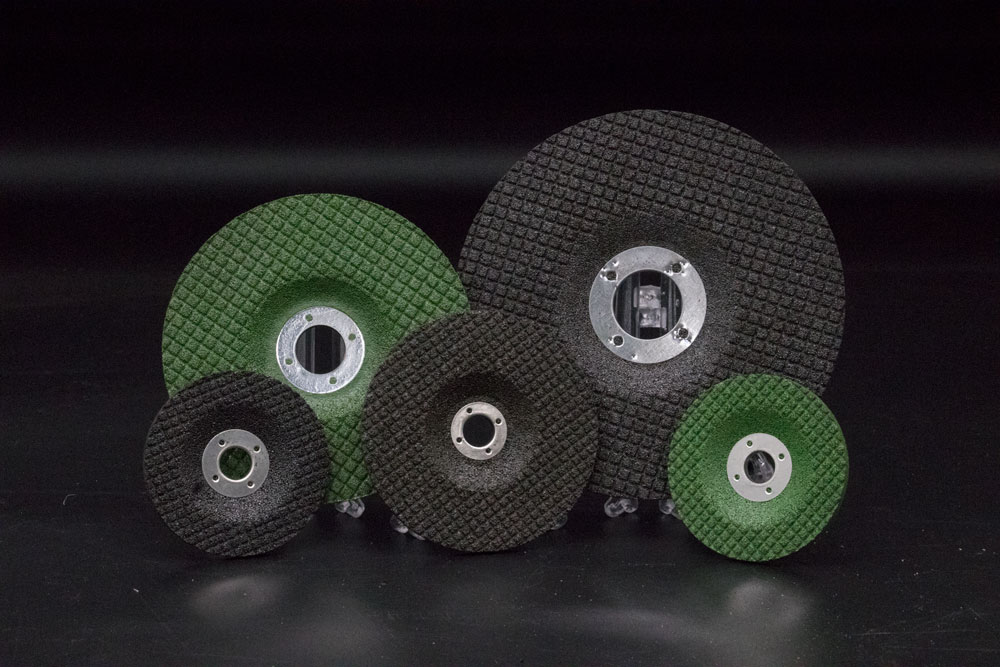

A Type 27 grinding wheel is a flat, disc-shaped tool used primarily for grinding and cutting metals, though they can be used on other materials like stone or ceramics. The “Type 27” refers to a specific bonded abrasive wheel shape with a depressed center design. The shape of the wheel, which is slightly recessed in the middle, allows for easier access to the workpiece, making it ideal for surface grinding applications, particularly when working on flat surfaces or edges.

This type of wheel is most commonly used on angle grinders but can also be used with other equipment, depending on the application and wheel size.

Common Applications of Type 27 Grinding Wheels

Type 27 grinding wheels are incredibly versatile and can be used for various grinding and finishing tasks, including:

- Surface Grinding:

- These wheels are ideal for grinding large, flat surfaces or edges, providing a smooth finish without causing excessive heat buildup.

- Deburring:

- The depressed center allows users to get closer to the workpiece, making Type 27 wheels excellent for deburring metal parts and removing sharp edges after cutting or welding.

- Metal Fabrication:

- Ideal for grinding or smoothing out weld seams and other imperfections in metalworking projects.

- Sharpening:

- Type 27 wheels are great for sharpening tools, such as chisels, blades, or other metal cutting tools.

- Smoothing & Finishing:

- Achieving a fine, smooth surface finish on a variety of materials, particularly metals like stainless steel, aluminum, and carbon steel.

Advantages of Type 27 Grinding Wheels

- Easy to Use: The recessed design of Type 27 grinding wheels allows users to apply the wheel to the surface of the material without difficulty, making it easier to grind and polish.

- Better Access: The design offers better access to tighter spaces, such as edges or corners, where other types of wheels may struggle.

- Versatility: Suitable for use on multiple materials, including metal, stone, and concrete.

- Safety Features: Type 27 grinding wheels are often designed with built-in safety features such as reinforced fiberglass or steel cores to prevent breakage during operation.

- Durability: These wheels are made to withstand high pressure and long periods of use, making them ideal for demanding industrial environments.

Choosing the Right Type 27 Grinding Wheel

When selecting a Type 27 grinding wheel, it’s important to consider the following factors:

- Material Compatibility:

- Ensure the wheel is suitable for the material you are working with, whether it’s metal, concrete, or other materials.

- Grit Size:

- Different applications require different levels of abrasiveness. Coarser grits are ideal for heavy material removal, while finer grits are better for finishing and polishing tasks.

- Wheel Diameter:

- Consider the size of the wheel that will best suit your tool and the type of job you are performing. Common diameters for Type 27 wheels include 4-1/2″, 5″, 7″, and 9″.

- Speed Rating:

- Ensure the wheel is rated for the RPM (revolutions per minute) of your grinder to avoid accidents.

- Bond Material:

- The bond material, such as resin or vitrified bonds, affects the wheel’s ability to withstand heat and pressure, influencing its lifespan and performance.

Safety Tips for Using Type 27 Grinding Wheels

Like all abrasive tools, safety is paramount when using Type 27 grinding wheels. Follow these guidelines to ensure safe operation:

- Use Protective Gear: Always wear safety goggles, gloves, and a face shield when grinding to protect against flying debris.

- Check the Wheel for Damage: Inspect the wheel before each use for cracks, chips, or other damage. Replace any damaged wheels immediately.

- Use the Correct RPM: Always check that the grinding wheel’s speed rating matches the grinder’s RPM to prevent accidents.

- Proper Handling: Hold the grinder firmly and maintain proper control to avoid kickback.

- Keep the Work Area Clean: Ensure the work area is free of flammable materials and that there is proper ventilation.

Conclusion

Type 27 grinding wheels are a reliable and versatile tool in the world of metalworking and construction. Their recessed center design provides excellent access to the workpiece, making them ideal for surface grinding, deburring, and finishing tasks. By understanding the wheel’s features, applications, and safety considerations, you can select the right wheel for your project and ensure safe and effective results every time.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address