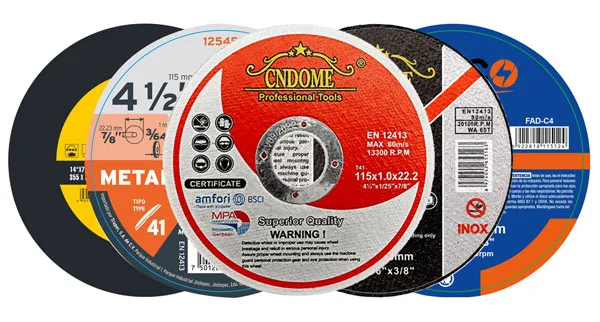

When it comes to cutting through metals with precision, speed, and minimal heat buildup, ultra-thin cutting wheels are a game-changer. These cutting discs, typically measuring around 0.8mm to 1mm in thickness, offer unparalleled performance for professionals in industries ranging from metal fabrication to automotive repairs. Here’s why ultra-thin cutting discs are becoming the go-to tool for metalworkers, welders, and manufacturers alike.

1. High Precision and Clean Cuts

Ultra-thin cutting wheels are designed to deliver clean, accurate cuts with minimal burrs or slag. Their thin profile allows them to slice through materials with much less resistance than thicker wheels, ensuring a sharp edge and reducing the need for additional finishing or cleaning work. This makes them ideal for projects that demand high levels of accuracy, such as in precision metalworking, automotive body repairs, and thin sheet metal cutting.

2. Faster Cutting Speed

Due to their thinner design, ultra-thin cutting discs typically provide faster cutting speeds compared to their thicker counterparts. The reduced thickness means that there is less material for the wheel to grind through, resulting in quicker, more efficient cuts. This feature is particularly valuable in industries where productivity and time savings are crucial.

3. Less Heat Generation

One of the primary advantages of ultra-thin cutting wheels is their ability to generate significantly less heat during cutting. The minimal material contact means that the workpiece experiences less thermal stress, reducing the risk of heat distortion or discoloration. This is especially important when cutting heat-sensitive materials like stainless steel, aluminum, and titanium.

4. Minimal Material Loss

Because ultra-thin cutting wheels have a smaller profile, they also result in minimal material loss during cutting. This can make a significant difference when working with expensive metals or when precision is paramount. The thinner the wheel, the less material is removed, leading to reduced wastage and more efficient use of raw materials.

5. Long Service Life

Despite their thinness, high-quality ultra-thin cutting discs are designed to offer a long service life. They’re made from durable abrasives such as aluminum oxide or zirconia, allowing them to maintain their cutting edge longer than some other types of cutting discs. Properly chosen and maintained ultra-thin cutting wheels can reduce downtime and increase overall productivity.

6. Applications in Various Industries

Ultra-thin cutting wheels are versatile tools that can be used across a wide range of applications:

- Automotive Repairs: Cutting through thin metal panels and components with precision.

- Sheet Metal Fabrication: Ideal for cutting intricate designs or thin metal sheets.

- Stainless Steel Cutting: Reducing heat generation to maintain the integrity of stainless steel surfaces.

- Construction and Renovation: Quick and precise cutting of pipes, rods, and other materials in tight spaces.

- Electronics Manufacturing: Cutting delicate components without damaging them.

7. Choosing the Right Ultra Thin Cutting Wheel

While ultra-thin cutting discs offer a variety of benefits, it’s important to choose the right wheel for the job. Factors like the type of material, cutting speed, and machine compatibility should all be taken into account. For instance, harder materials like stainless steel may require a wheel with a more specialized abrasive material, like zirconia, while softer materials like aluminum may benefit from a silicon carbide wheel.

Additionally, always consider the arbor size, diameter, and RPM limits to ensure safety and efficiency while using ultra-thin cutting wheels.

Conclusion

Ultra-thin cutting wheels are more than just a cutting tool—they’re a solution that enhances precision, speed, and efficiency in metal cutting. Whether you’re working on a complex automotive repair, creating intricate metal designs, or tackling a high-speed production line, these cutting wheels will help you get the job done quickly and with exceptional accuracy. By reducing heat buildup, minimizing material loss, and speeding up the cutting process, ultra-thin cutting wheels prove to be an indispensable tool for professionals across many industries.

Want to optimize your cutting process? Consider upgrading to ultra-thin cutting discs today and experience the difference in your cutting performance!