When it comes to precision cutting in various applications, choosing the right cut-off wheel is essential. One of the most popular sizes for both professionals and DIY enthusiasts is the 4.5″ cut-off wheel with a 5/8″ arbor. This combination offers versatility, efficiency, and compatibility with a wide range of tools. Let’s delve into what makes this particular size and arbor configuration so effective and how you can choose the best one for your needs.

What is a Cut-Off Wheel?

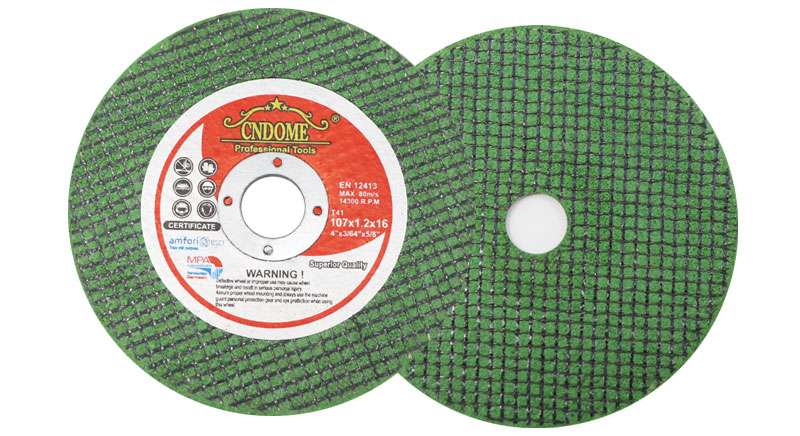

A cut-off wheel, also known as a cutting disc, is a thin, flat circular abrasive tool used for cutting through various materials such as metal, stone, and ceramics. These wheels are typically made from abrasive grains bonded together with resin, making them capable of precise and efficient cutting.

Why 4.5″ Cut-Off Wheels?

The 4.5″ diameter is a common size for cut-off wheels due to its balance between size and cutting capability. It is small enough to allow for detailed work and control, yet large enough to handle more substantial cutting tasks. This size is particularly favored in metalworking, fabrication, and construction industries.

Understanding the 5/8″ Arbor

The arbor size of a cut-off wheel refers to the diameter of the hole in the center of the wheel that fits onto the spindle of the cutting tool. A 5/8″ arbor is a standard size that fits many angle grinders and other cutting tools. This standardization ensures that the wheel can be easily mounted and securely fastened, providing stability and safety during operation.

Key Features of a 4.5″ Cut-Off Wheel with a 5/8″ Arbor

- Versatility: These wheels are suitable for cutting various materials, including stainless steel, mild steel, aluminum, and more. This makes them an excellent choice for diverse applications, from automotive work to plumbing and construction.

- Precision: The thin profile of the 4.5″ cut-off wheel allows for precise cuts, reducing material waste and improving the accuracy of your work.

- Efficiency: These wheels offer a good balance of cutting speed and longevity. They are designed to cut quickly and efficiently without sacrificing durability.

- Compatibility: The 5/8″ arbor size ensures that these wheels can be used with a wide range of cutting tools, making them a versatile addition to your toolkit.

Choosing the Right 4.5″ Cut-Off Wheel

When selecting a cut-off wheel, consider the following factors:

- Material: Ensure the wheel is designed for the specific material you will be cutting. For example, wheels designed for cutting stainless steel will differ from those intended for cutting stone or aluminum.

- Abrasive Type: Different abrasive materials (such as aluminum oxide, zirconia alumina, or silicon carbide) offer varying performance characteristics. Choose the abrasive type that best suits your cutting needs.

- Bonding Agent: The bonding agent holds the abrasive grains together. Resin-bonded wheels are common for cut-off applications, providing a good balance of performance and safety.

- Thickness: Thinner wheels (e.g., 0.040″ or 1mm) offer faster cutting with less material waste, while thicker wheels provide greater durability for heavier cutting tasks.

- Brand and Quality: Opt for reputable brands known for producing high-quality, reliable cut-off wheels. Investing in a well-made product can enhance both safety and performance.

Safety Tips

- Wear Proper PPE: Always wear safety goggles, gloves, and hearing protection when using cut-off wheels.

- Inspect Before Use: Check the wheel for any cracks, chips, or other damage before mounting it on your tool.

- Follow Manufacturer’s Instructions: Adhere to the recommended operating speed and usage guidelines provided by the manufacturer.

- Secure Your Workpiece: Ensure the material you are cutting is securely clamped to prevent movement during cutting.

- Use the Right Tool: Make sure your tool is compatible with the wheel size and arbor configuration.

Conclusion

A 4.5″ cut-off wheel with a 5/8″ arbor is a versatile and essential tool for many cutting applications. By understanding its features and selecting the right wheel for your specific needs, you can achieve precise, efficient, and safe cutting results. Whether you’re a professional or a DIY enthusiast, having these wheels in your arsenal will undoubtedly enhance your cutting capabilities.