A cutting disc factory is a place where precision, innovation, and safety meet to produce the essential tools for metalworking, construction, and manufacturing industries. These factories are the backbone of the abrasive tool industry, producing cutting discs that are used across various applications, from metal cutting to stonework. In this blog, we will take a closer look at how cutting discs are made, the technology behind their production, and the importance of quality control in the factory.

1. The Basics of Cutting Discs

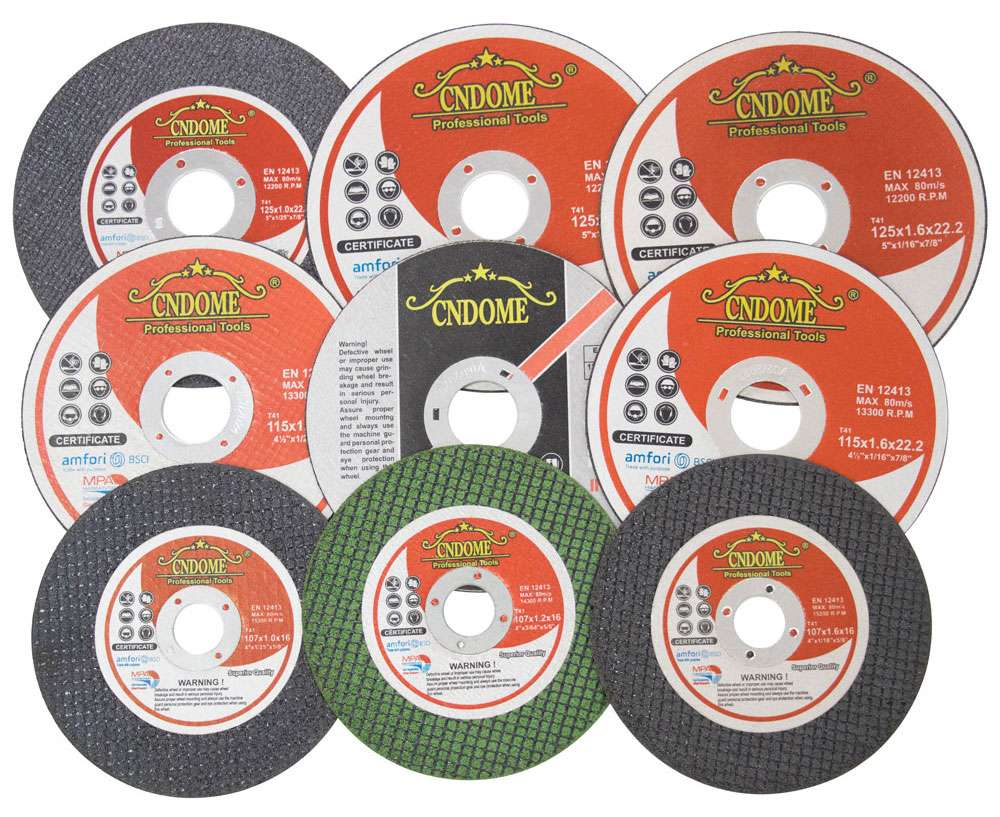

Cutting discs, also known as cutting wheels or blades, are tools used for cutting through hard materials such as metal, stone, and concrete. They are made from abrasive grains like aluminum oxide, silicon carbide, and other synthetic materials that provide the necessary hardness and cutting power. Cutting discs come in different sizes, shapes, and thicknesses, with specific discs designed for particular materials and applications.

2. The Manufacturing Process

The production of cutting discs is a detailed and meticulous process, requiring precision and attention to detail. Here’s an overview of the typical manufacturing steps involved:

- Material Selection: The process begins with selecting the right abrasive material. Depending on the intended application (metal, concrete, stone, etc.), manufacturers choose specific types of abrasives that offer the best cutting performance and durability.

- Bonding: Abrasive grains are mixed with a bonding agent, such as resin or vitrified bonds, to create a stable mixture. The bonding agent holds the abrasive grains in place and ensures that the disc remains intact during use.

- Shaping the Disc: The mixture is placed into molds to shape the disc. The molds come in various sizes, typically ranging from 3 inches to 14 inches in diameter. The discs are pressed into shape under high pressure.

- Curing: After shaping, the discs are cured in an oven at high temperatures. This step hardens the bonding material, allowing the abrasive grains to stay firmly in place during cutting. The curing process also ensures the disc is strong and stable under pressure.

- Grinding and Finishing: Once the disc is cured, it undergoes further grinding to smooth out rough edges and ensure consistency. At this stage, the discs are also balanced to reduce vibration during use, which could affect cutting efficiency and safety.

- Quality Control: Every cutting disc undergoes rigorous testing for quality and performance. This includes checking for uniformity in shape, size, and thickness, as well as ensuring the bonding material is evenly distributed. Tests are conducted to assess the disc’s strength, durability, and resistance to wear.

3. Key Technologies in Cutting Disc Factories

Cutting disc factories employ a range of technologies to improve manufacturing efficiency and product quality. Here are a few examples:

- CNC Machines: Computer Numerical Control (CNC) machines are used for precision shaping and cutting, ensuring that each disc meets the exact specifications required.

- Automatic Presses: These presses provide consistent pressure during the forming process, ensuring uniformity in the discs’ thickness and shape.

- Laser Cutting: For certain applications, laser cutting technology is used to create ultra-precise discs with minimal wastage.

- Advanced Bonding Systems: Newer bonding technologies are continuously being developed to create stronger, longer-lasting bonds between the abrasive grains and the disc material.

4. Importance of Quality Control

In a cutting disc factory, quality control is paramount. A poorly made cutting disc can lead to safety hazards and subpar performance, costing time and money for the user. To ensure each disc meets stringent standards, factories often have dedicated quality control teams that perform the following tasks:

- Visual Inspections: Inspecting the disc for cracks, irregularities, or defects in shape or size.

- Performance Testing: Conducting cutting tests to assess the disc’s effectiveness and longevity in real-world applications.

- Safety Checks: Ensuring that the cutting discs are free from any safety hazards, such as cracks or weak spots that could lead to breakage during use.

- Certifications and Standards: Adhering to industry standards such as ISO 9001 for quality management and other safety certifications to ensure the discs meet global market requirements.

5. Sustainability in Cutting Disc Factories

With increasing environmental awareness, many cutting disc factories are adopting sustainable practices. These practices include:

- Recycling Materials: Some factories recycle waste materials from the manufacturing process to reduce environmental impact.

- Energy Efficiency: Implementing energy-efficient technologies to reduce the carbon footprint of the production process.

- Eco-friendly Materials: Using non-toxic, sustainable raw materials to minimize environmental harm.

6. Customizing Cutting Discs for Specific Needs

Cutting disc factories often offer OEM (Original Equipment Manufacturer) services, allowing customers to customize their cutting discs for specific applications. This can include tailoring the abrasive material, size, thickness, bond type, and even adding branding or logos to the discs. Customization ensures that businesses get the right tool for their needs, whether it’s for cutting specific materials, achieving particular performance characteristics, or fitting into a particular tool or machine.

7. Challenges Faced by Cutting Disc Factories

Running a cutting disc factory comes with its own set of challenges. These include:

- Maintaining Consistent Quality: Achieving consistent quality across large production runs can be difficult, especially when working with varying raw materials or adapting to new technologies.

- Cost Management: The rising cost of raw materials and energy can impact the price of the final product, making cost control a key focus for manufacturers.

- Meeting Diverse Customer Needs: As industries evolve, so do the needs of customers. Factories must keep up with trends and technological advancements to remain competitive.

- Global Competition: The cutting disc market is highly competitive, with manufacturers from around the world vying for market share. Factories must continuously innovate and improve to stay ahead.

Conclusion

Cutting disc factories are highly specialized environments where technology, skill, and innovation come together to produce essential tools that make a wide range of industrial tasks possible. From the selection of raw materials to the final quality control tests, each step in the production process is crucial to ensuring that the discs perform safely and effectively. As demand for more advanced, customized, and eco-friendly products grows, cutting disc factories will continue to evolve, driving the future of the abrasive tool industry.