Abrasive wheels are a staple in various industrial and DIY applications, offering unmatched efficiency in cutting, grinding, and polishing tasks. Among the different types of abrasive wheels, Type 1 wheels are particularly popular for their versatility and performance. In this blog, we’ll delve into what makes Type 1 abrasive wheels unique, their applications, and tips for choosing the right one for your needs.

What are Type 1 Abrasive Wheels?

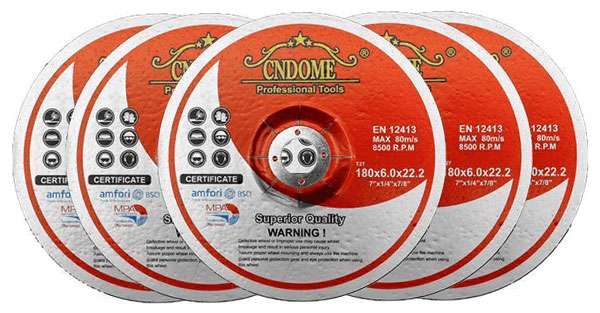

Type 1 abrasive wheels, also known as straight wheels, have a flat, disk-like shape with a uniform thickness. They are designed for use in grinding machines and are commonly employed for cutting, grinding, and finishing tasks. The wheel’s cutting edge is located on the periphery, making it ideal for straight cuts and surface grinding.

Key Features and Benefits

1. Versatility: Type 1 wheels can be used on various materials, including metal, stainless steel, and other hard substances. This makes them suitable for a wide range of applications in different industries.

2. Efficiency: These wheels offer efficient material removal, which can significantly speed up the grinding or cutting process. Their design allows for precise cuts and smooth finishes.

3. Durability: High-quality Type 1 wheels are made from robust materials that ensure a long lifespan, even under heavy-duty use. This durability translates to cost savings over time.

4. Safety: When used correctly, Type 1 abrasive wheels are safe and reliable. Their flat design helps maintain stability during operation, reducing the risk of accidents.

Common Applications

Type 1 abrasive wheels are used in various applications, including:

- Metal Fabrication: Cutting and grinding metal components to size or shape.

- Automotive: Removing rust, paint, and other surface contaminants.

- Construction: Cutting and shaping construction materials like steel beams and rebar.

- DIY Projects: Home improvement tasks that involve metalworking or detailed grinding.

Choosing the Right Type 1 Abrasive Wheel

When selecting a Type 1 abrasive wheel, consider the following factors:

- Material: Ensure the wheel is compatible with the material you’ll be working on. Different materials require specific abrasive compositions for optimal performance.

- Wheel Diameter: Choose a wheel size that fits your grinding machine and suits the scale of your project. Larger wheels cover more surface area but may be less precise, while smaller wheels offer greater control.

- Abrasive Grain: The type of abrasive grain (e.g., aluminum oxide, silicon carbide) affects the wheel’s cutting ability and finish quality. Select a grain that matches your material and desired outcome.

- Bond Type: The bond holds the abrasive grains together. Common types include vitrified, resinoid, and metal bonds. Each bond type offers different levels of durability and cutting speed.

- Grit Size: The grit size determines the wheel’s coarseness. Coarser grits remove material faster but leave a rougher finish, while finer grits provide a smoother finish.

Conclusion

Type 1 abrasive wheels are indispensable tools in many industries, offering versatility, efficiency, and durability. By understanding their features and applications, you can make informed choices that enhance your projects and ensure safe, effective operation. Whether you’re a professional metalworker or a DIY enthusiast, Type 1 grinding wheels are a valuable addition to your toolkit.