Abrasive wheels are essential tools in many industries, ranging from metalworking to construction. Among the various types, Type 1 grinding wheels are particularly popular due to their versatility and efficiency. In this blog, we’ll delve into what Type 1 abrasive wheels are, their applications, benefits, and some tips for selecting the right one for your needs.

What are Type 1 Abrasive Wheels?

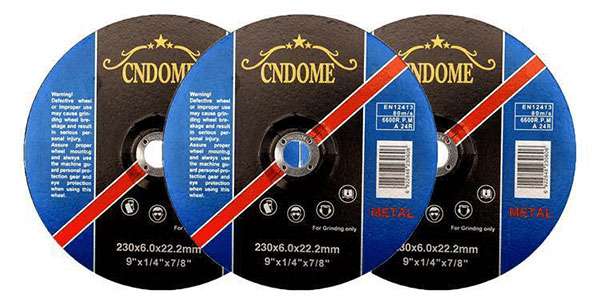

Type 1 abrasive wheels, also known as straight wheels, are flat wheels with a simple, straight profile. They are designed for use on stationary and portable grinders and are typically used for cutting, grinding, and sharpening.

Applications of Type 1 Abrasive Wheels

Type 1 wheels are widely used in various industries due to their versatility. Some common applications include:

- Cutting Metal: These wheels are ideal for cutting through various types of metal, including steel, stainless steel, and other alloys. Their thin profile allows for precise cuts with minimal material waste.

- Grinding: Type 1 wheels are used for grinding operations, such as deburring, surface preparation, and weld removal. They provide a smooth finish and can handle high-pressure applications.

- Sharpening Tools: They are also used for sharpening tools and equipment, ensuring a sharp edge for optimal performance.

Benefits of Using Type 1 Abrasive Wheels

- Precision: The flat, straight profile of Type 1 wheels allows for precise cuts and smooth finishes.

- Versatility: Suitable for both cutting and grinding, these wheels can be used on a variety of materials and applications.

- Durability: Made from high-quality abrasive materials, Type 1 wheels are designed to withstand heavy use and high-pressure applications.

- Efficiency: These wheels are designed to remove material quickly and efficiently, reducing downtime and increasing productivity.

Selecting the Right Type 1 Abrasive Wheel

When choosing a Type 1 abrasive wheel, consider the following factors:

- Material: Ensure the wheel is suitable for the material you are working with. Different materials require different abrasive compositions for optimal performance.

- Grit Size: Choose the appropriate grit size based on the finish you need. Coarser grits are ideal for rapid material removal, while finer grits provide a smoother finish.

- Wheel Diameter and Thickness: Select a wheel with the right diameter and thickness for your specific tool and application.

- Bond Type: The bond type affects the wheel’s performance and longevity. Common bond types include vitrified, resin, and metal bonds, each with its own advantages.

Safety Tips

- Wear Proper PPE: Always wear safety glasses, gloves, and other personal protective equipment when using abrasive wheels.

- Inspect the Wheel: Before use, inspect the wheel for any signs of damage or wear. Do not use a damaged wheel.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for speed, usage, and maintenance.

Conclusion

Type 1 abrasive wheels are a versatile and efficient choice for various cutting, grinding, and sharpening applications. By understanding their benefits and how to select the right wheel, you can enhance your productivity and achieve superior results in your projects. Always prioritize safety and follow best practices to ensure a smooth and safe operation.

Feel free to share or modify this blog post to suit your needs!

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address