The three main types of abrasive wheels are:

1. Grinding Wheels:

Grinding wheels are the most common type of abrasive wheel. They are used for grinding, deburring, and shaping various materials, including metal, steel, concrete, and stone. Grinding wheels consist of abrasive grains bonded together with a matrix, such as vitrified (ceramic), resin, rubber, or metal. They come in various shapes and sizes to suit different applications, and the choice of grinding wheel depends on the material being worked on and the desired finish.

2. Cut-off Wheels (Cutting Wheels):

Cut-off wheels, also known as cutting wheels or abrasive discs, are designed primarily for cutting through metal, but they can also be used on other materials like plastic and ceramics. These wheels are thin and reinforced with fiberglass mesh to provide strength and durability during cutting operations. Cut-off wheels create clean, precise cuts and are commonly used in metal fabrication, construction, and automotive repair.

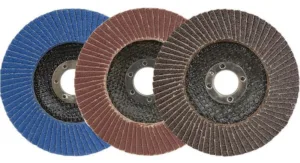

3. Flap Wheels:

Flap wheels are unique in their design, featuring flaps of abrasive material radiating outward from a central hub. They are used for blending, deburring, and finishing tasks on a variety of surfaces, including metal, wood, and plastics. Flap wheels are flexible and conform to irregular shapes, making them ideal for contour sanding and achieving a smooth, uniform finish. They are commonly used in woodworking, metalworking, and surface preparation.

These three main types of abrasive wheels serve distinct purposes and are chosen based on the specific requirements of the task at hand. It’s crucial to select the right type of abrasive wheel, considering factors like the material being worked on, the desired finish, and safety considerations. Additionally, always follow the manufacturer’s guidelines and safety precautions when using abrasive wheels to ensure safe and effective operations.