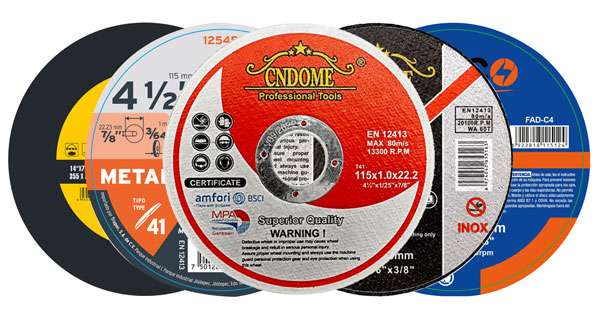

4.5 inch cutting discs are commonly used for cutting metal, such as steel and iron, in farm workshops. When selecting a 4.5 inch cutting disc, you should consider factors such as the type of material you will be cutting, the thickness of the material, the speed of the disc, and the durability of the disc.

It is important to select a cutting disc that is appropriate for the material you will be cutting. Using the wrong type of disc can result in inefficient cutting, damage to the disc, and even injury. Some common types of cutting discs include abrasive discs, diamond discs, and carbide discs.

You should also consider the thickness of the material you will be cutting. Thicker materials will require a more powerful 4.5 inch cutting disc. It is important to select a cutting disc that is capable of cutting through the material without causing damage to the disc or the tool.

The speed of the cutting disc is also an important factor. A faster cutting disc will typically result in quicker and more efficient cuts. However, it is important to ensure that the disc is being used at a safe speed to avoid accidents or injury.

Finally, you should consider the durability of your cutting disc. High-quality cutting wheels last longer and need to be replaced less frequently. Saves you money in the long run. It is also important to use cut-off wheels according to the manufacturer’s instructions. In order to ensure its service life as long as possible.