When it comes to abrasive tools, flap discs are essential workhorses in the world of metalworking and grinding. But what makes one flap disc outshine the rest? The answer lies in the material. Choosing the best material for your flap discs can make a significant difference in performance, durability, and cost-effectiveness. In this blog post, we dive into the world of flap discs and explore the key materials that set the best ones apart.

Understanding Flap Discs

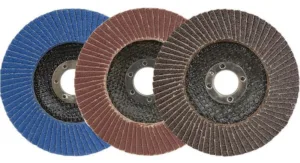

Before we dive into materials, let’s get a quick overview of flap discs. These versatile tools are used for grinding, sanding, and finishing various materials, including metal, wood, and plastic. They consist of a circular, flat disc with overlapping abrasive flaps or “flaps” that are bonded to a backing plate. The flaps can be made from different materials, and it’s this material that largely determines the disc’s effectiveness.

Flap Disc Material Options

Flap discs are available in different materials, each with its own set of advantages. The choice of material depends on your specific application and requirements. Let’s explore some common flap disc materials:

Aluminum Oxide: Aluminum oxide is a versatile and widely used material for flap discs. It is ideal for general-purpose applications and excels at grinding and finishing various metals, including steel, aluminum, and stainless steel. It offers a good balance between performance and cost-effectiveness.

Zirconia Alumina: Zirconia alumina flap discs are known for their exceptional durability and long lifespan. They are excellent for aggressive grinding on hard metals, such as stainless steel and high-alloy steels. Zirconia alumina discs are heat-resistant and maintain their cutting ability even at high temperatures.

Ceramic Alumina: Ceramic alumina flap discs are the top choice for heavy-duty applications. They are extremely tough and provide rapid material removal. These discs are often used for grinding hard metals and are known for their superior heat resistance and longevity.

Silicon Carbide: Silicon carbide flap discs are typically used for finishing non-ferrous metals, such as brass, copper, and aluminum. They are also effective for sanding and shaping wood and plastics. Silicon carbide is known for its fine finish and flexibility.

Choosing the Best Material for Your Needs

The best material for your flap disc depends on the specific task at hand. Here are some general guidelines to help you make an informed choice:

Aluminum Oxide: Choose aluminum oxide for general-purpose grinding and finishing on a variety of metals.

Zirconia Alumina: Opt for zirconia alumina when working with harder metals like stainless steel or when you need extended durability.

Ceramic Alumina: Select ceramic alumina for heavy-duty, high-temperature applications and when you need maximum material removal.

Silicon Carbide: Use silicon carbide for finishing non-ferrous metals, wood, and plastics.

In conclusion, the best material for flap discs depends on the specific application and the material you are working with. Selecting the right material ensures optimal performance and a longer lifespan for your abrasive tool. Remember to consider factors such as material hardness, heat resistance, and the desired finish when making your choice.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address