In the world of metal fabrication, the quest for the perfect finish is a relentless pursuit. If you’re working with stainless steel, you know that achieving that mirror-like shine requires not only skill but also the right tools. Enter Stainless Steel Flap Discs — the unsung heroes of metalworking that bring precision, efficiency, and a touch of finesse to your projects.

Why Stainless Steel Flap Discs?

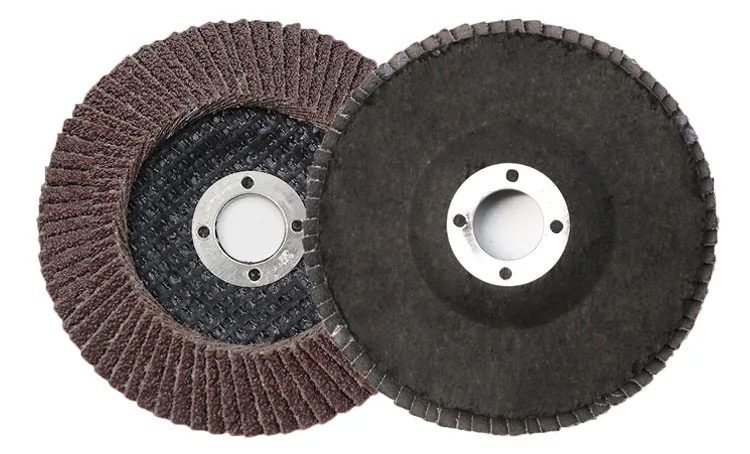

1. Flawless Finishes: Stainless steel is renowned for its aesthetic appeal, but achieving a flawless finish can be a challenge. Stainless steel flap disks are engineered with layers of abrasive material arranged in a fan-like pattern. This design allows for controlled material removal, ensuring a consistent and smooth surface finish.

2. Versatility Unleashed: Whether you’re grinding, blending, or finishing, stainless steel flap disks are versatile multitaskers. They adapt to contours and curves with ease, making them indispensable for intricate work where precision is non-negotiable.

3. Efficiency Redefined: Time is money, and stainless steel flap discs are a wise investment. The unique design reduces the need for multiple tools, streamlining your workflow. These discs cut through stainless steel with efficiency, saving you time and effort.

4. Durability Matters: Stainless steel can be unforgiving, and your tools need to stand up to the challenge. Flap discs, with their sturdy construction, are built to last. They resist wear and tear, providing consistent performance even in demanding applications.

5. Minimized Heat Buildup: Excessive heat can compromise the integrity of stainless steel. Stainless steel flap disks are designed to minimize heat buildup during operation. This not only preserves the quality of your work but also enhances safety by reducing the risk of overheating.

Applications of Stainless Steel Flap Discs:

1. Weld Seam Blending: Perfect welds demand seamless blending. Stainless steel flap discs are your go-to tools for achieving smooth transitions and eliminating weld seams with precision.

2. Surface Preparation: Before painting or coating, proper surface preparation is essential. Stainless steel flap disks make quick work of rust, oxidation, and other surface imperfections, ensuring a clean canvas for your finishing touches.

3. Deburring and Chamfering: Smooth edges are not just a cosmetic preference; they’re a necessity. Flap discs are excellent for deburring and chamfering, leaving edges clean and free from imperfections.

4. Grinding and Stock Removal: From heavy stock removal to fine grinding, stainless steel flap disks offer a controlled yet aggressive approach, allowing you to tailor your process to the specific needs of your project.

Why Choose Our Stainless Steel Flap Discs?

Premium Quality: Our flap discs are crafted from high-quality materials, ensuring durability and consistent performance.

Precision Engineering: Every design aspect is meticulously crafted for optimal efficiency and precision in metalworking.

Safety Assurance: With reduced vibration and minimized kickback, our stainless steel flap disks prioritize your safety without compromising on performance.

Conclusion: Elevate Your Craft with Stainless Steel Flap Discs

Say goodbye to the days of struggling with imperfect finishes and inefficient tools. Upgrade your metalworking arsenal with stainless steel flap discs — the secret weapon for achieving unparalleled precision and efficiency in every project. Experience the transformation and let your work shine!

Explore our range today and discover the brilliance of stainless steel flap disks! Elevate your metalworking game with Dome.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address