Angle grinders have become indispensable tools in the arsenal of both professional tradespeople and DIY enthusiasts. Among the numerous attachments and accessories available for these versatile machines, metal cutting discs stand out as crucial components for tasks ranging from fabrication to renovation. In this blog post, we’ll explore the key features, types, and benefits of metal cutting discs designed for angle grinders.

Understanding Metal Cutting Discs:

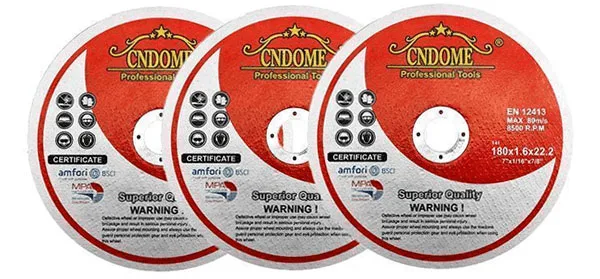

Metal cutting discs, also known as cutting wheels or abrasive discs, are engineered to precisely slice through various metals with speed and precision. These discs are commonly used in angle grinders, providing a dynamic and efficient method for cutting, shaping, and grinding metal surfaces. The design and composition of these discs play a pivotal role in determining their effectiveness and durability.

Key Features:

1. Material Composition:

Metal cutting discs are typically made from materials like aluminum oxide, silicon carbide, or zirconia alumina. The choice of material depends on the specific application and the type of metal being cut.

2. Thickness:

The thickness of the cutting disc affects its performance. Thicker discs are generally more durable and suitable for heavy-duty tasks, while thinner discs provide faster cutting but may wear out more quickly.

3. Diameter:

Metal cutting discs come in various diameters, ranging from 4 inches to 9 inches or more. The choice of diameter depends on the size of the angle grinder and the specific requirements of the job.

4. Reinforcement:

Many cutting discs feature fiberglass reinforcement to enhance strength and prevent breakage during operation. This reinforcement is crucial for safety and longevity.

Types of Metal Cutting Discs:

1. Bonded Abrasive Discs:

These discs are made by bonding abrasive grains to a matrix material. They are ideal for general-purpose cutting and are available in various compositions for cutting different metals.

2. Diamond Cutting Discs:

Designed for cutting hard and abrasive materials, diamond cutting discs use industrial diamonds embedded in the disc’s matrix. They are highly effective for cutting through materials like steel, concrete, and ceramic.

Benefits of Metal Cutting Discs for Angle Grinders:

1. Precision and Speed:

Metal cutting discs offer precise and fast cutting, allowing for efficient material removal and shaping.

2. Versatility:

These discs can handle a wide range of metals, making them versatile tools suitable for various applications.

3. Cost-Effective:

Metal cutting discs are cost-effective tools compared to other cutting methods, making them a preferred choice for many professionals and DIYers.

4. Ease of Use:

Angle grinders equipped with metal cutting discs are user-friendly and provide a portable solution for on-site cutting tasks.

Conclusion:

Metal cutting discs for angle grinders are indispensable tools for professionals and DIY enthusiasts alike. Understanding the key features and types of these discs allows users to choose the right tool for the job, ensuring precision, efficiency, and safety in metal cutting applications. Whether you’re a seasoned professional or a hobbyist, the right metal cutting disc can make a significant difference in the outcome of your projects.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

[email protected]

Address