In the realm of industrial tools and equipment, cutting discs play a crucial role in various applications, ranging from metal fabrication to construction. Among the myriad of cutting disc sizes available, the 230mm cutting discs stands out as a popular choice for many professionals. However, the popularity of this particular size can vary significantly from one country to another. In this blog post, we’ll delve into the factors influencing the popularity of 230mm cutting discs across different countries.

Understanding 230mm Cutting Discs:

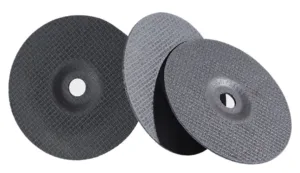

Before we delve into its popularity, let’s understand what sets the 230mm cutting disc apart. This disc size typically refers to the diameter of the cutting blade. A 230mm cutting disc is approximately 9 inches in diameter, making it suitable for a wide range of cutting tasks, including slicing through thick metal sheets, concrete, and other robust materials. Its versatility and ability to handle demanding cutting jobs make it a favored choice among professionals in various industries.

Factors Influencing Popularity:

- Industrial Practices: The popularity of 230mm cutting discs often aligns with prevalent industrial practices in a particular country. Nations with a robust manufacturing sector or significant construction activities tend to have a higher demand for these discs. For instance, countries with burgeoning infrastructure projects may witness a surge in the use of 230mm cutting discs due to their effectiveness in cutting concrete and metal beams.

- Market Availability: The availability of 230mm cutting disks in local markets also influences their popularity. Countries with well-established distribution networks for industrial tools are likely to see higher adoption rates. Additionally, the presence of reputable brands offering quality 230mm cutting disks can further contribute to their popularity.

- Regulatory Standards: Compliance with safety and regulatory standards plays a crucial role in determining the popularity of cutting discs. Countries with stringent safety regulations are likely to see greater adoption of 230mm cutting discs that meet or exceed these standards. Professionals prioritize safety when selecting cutting tools, making compliance with regulations a significant factor in their choice.

- Economic Factors: Economic conditions and pricing also impact the popularity of 230mm cutting disks. In regions where labor costs are high, professionals may opt for efficient cutting tools like the 230mm disc to enhance productivity and minimize labor expenses. Similarly, competitive pricing of these discs compared to alternative cutting methods can drive their popularity in cost-conscious markets.

Global Perspectives:

Now, let’s explore the popularity of 230mm cutting discs in various countries:

- Germany: Known for its precision engineering and manufacturing prowess, Germany exhibits a high demand for 230mm cutting disks, particularly in industries such as automotive, machinery, and construction.

- China: As a manufacturing powerhouse with extensive construction activities, China sees widespread use of 230mm cutting discs in both industrial and residential construction projects.

- United States: In the US, the popularity of 230mm cutting disks varies by region, with significant adoption in states with thriving construction and manufacturing sectors such as California, Texas, and New York.

- Australia: With its focus on infrastructure development and mining projects, Australia witnesses considerable demand for 230mm cutting discs, especially in sectors like mining, oil, and gas.

Conclusion:

The popularity of 230mm cutting discs is influenced by a myriad of factors, including industrial practices, market availability, regulatory standards, and economic considerations. While their adoption may vary from one country to another, these discs remain indispensable tools for professionals across diverse industries, showcasing their versatility and effectiveness in tackling challenging cutting tasks. As industrial practices evolve and market dynamics shift, the popularity of 230mm cutting disks is likely to continue evolving, reflecting the dynamic nature of the global industrial landscape.