In the ever-evolving landscape of manufacturing and fabrication, precision is paramount. Whether you’re a seasoned professional or an aspiring craftsman, the tools you use can make all the difference. Enter cutting discs for die grinders – small but mighty tools that wield immense power in shaping, cutting, and finishing various materials with finesse and accuracy. Let’s embark on a journey to unravel the significance of cutting discs for die grinders and delve into their applications, features, and benefits.

The Versatility of Die Grinders

Before we delve into cutting discs, let’s shed some light on die grinders themselves. Die grinders are handheld power tools known for their versatility and precision. They are widely used in metalworking, woodworking, automotive, and other industries for tasks such as grinding, polishing, deburring, and, of course, cutting. Their compact size and maneuverability make them indispensable for intricate jobs where larger tools may be impractical.

Introducing Cutting Discs

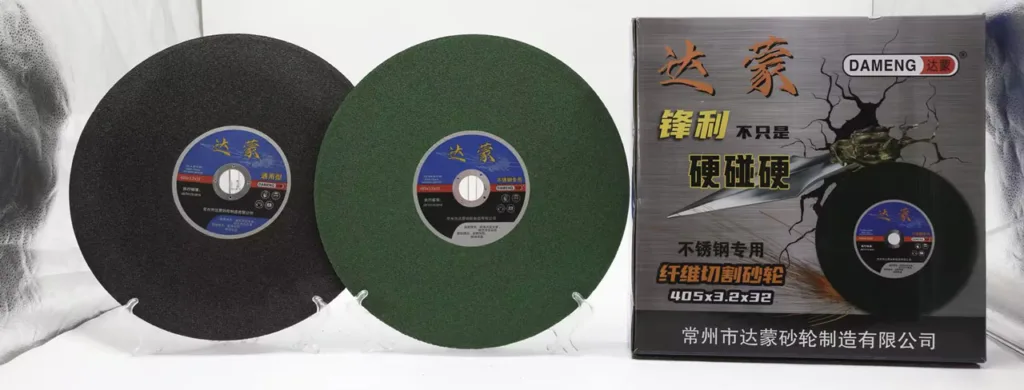

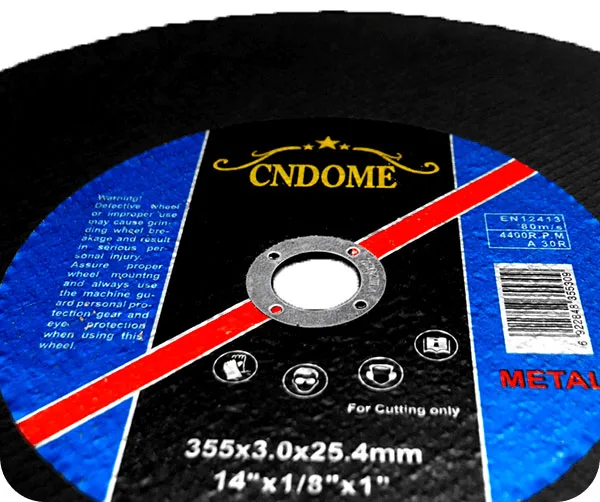

At the heart of a die grinder’s cutting prowess lies the cutting disc. These discs, also known as cutoff wheels or abrasive wheels, are precision-engineered discs made of abrasive materials bonded together. They come in various shapes and sizes, including flat, depressed center, and thin cutting discs, each designed for specific applications.

Applications and Materials

Cutting discs for die grinders are capable of slicing through a wide array of materials with ease. From metals like steel, aluminum, and stainless steel to non-metal materials such as plastics, fiberglass, and ceramics, these discs deliver precise cuts, making them indispensable in fabrication workshops, construction sites, and automotive garages.

Whether you’re trimming metal pipes, cutting sheet metal, or shaping composite materials, cutting diss for die grinders offer the versatility and performance needed to tackle diverse tasks with efficiency and accuracy.

Versatility Personified

Cutting discs for die grinders are true chameleons in the workshop, capable of tackling a myriad of materials with finesse. From steel and aluminum to ceramics and plastics, these discs exhibit versatility that knows no bounds. Whether you’re slicing through sheet metal, trimming bolts, or shaping intricate contours, cutting disks for die grinders rise to the occasion with unparalleled precision.

Types of Cutting Discs

Cutting discs for die grinders come in various types, each tailored to specific materials and applications. Some common types include:

- Metal Cutting Discs: Designed specifically for slicing through metal sheets, rods, and pipes with precision and speed.

- Masonry Cutting Discs: Engineered to tackle tough materials like concrete, brick, and stone, these discs offer exceptional cutting power and durability.

- Diamond Cutting Discs: Ideal for cutting through hard materials such as ceramics, glass, and tiles, diamond cutting discs offer unparalleled precision and longevity.

Safety Considerations

While cutting discs for die grinders are invaluable tools, safety should always remain a top priority. Users must wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection, to mitigate the risks associated with high-speed cutting operations. Additionally, ensuring proper installation and maintenance of cutting discs is crucial for safe and efficient operation.

Conclusion

In the world of precision engineering and fabrication, cutting discs for die grinders stand as indispensable tools, combining versatility, efficiency, and precision. From shaping and trimming to cutting and finishing, these discs empower craftsmen and professionals to unleash their creativity and achieve unparalleled results. So, the next time you reach for your die grinder, remember the cutting disc – a small yet powerful companion in your quest for precision and excellence.