Cutting discs are indispensable tools in various industries, from metalworking to construction. They provide precise cutting, shaping, and grinding functionalities, making them essential for tasks ranging from fabrication to maintenance. However, navigating the myriad options available in the market can be daunting, especially when trying to decode industry-specific coding systems like the IMPA (International Maritime Purchasing Association) code. In this blog, we’ll delve into the cutting disc IMPA code, unraveling its components and deciphering its significance.

Decoding the IMPA Code:

The IMPA code is a standardized system used in the maritime industry for the identification and classification of various products and equipment. It serves as a universal language for procurement, ensuring clarity and consistency in transactions across different regions and sectors. Understanding the IMPA code for cutting discs involves dissecting its structure:

1. Product Category:

The IMPA code begins with a series of digits representing the product category. For cutting discs, this category typically falls under abrasive tools or grinding equipment. The specific category code varies depending on the classification system used by different suppliers and manufacturers.

2. Product Type:

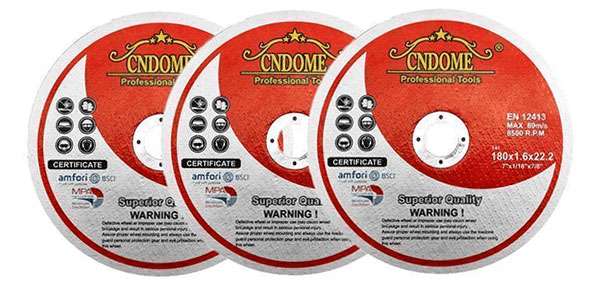

Following the product category, the IMPA code distinguishes between different types of cutting discs based on their specifications and intended applications. This segment of the code provides valuable information regarding the disc’s size, material composition, and cutting properties. Common variations include discs designed for metal, masonry, or general-purpose cutting.

3. Size and Dimensions:

Precision is paramount when selecting cutting discs, and the IMPA code reflects this by including detailed specifications regarding size and dimensions. These numerical values indicate the diameter, thickness, and bore size of the disc, ensuring compatibility with various cutting tools and machines. Additionally, certain codes may specify the maximum operating speed or RPM (Revolutions Per Minute) for optimal performance and safety.

4. Material Composition:

The composition of the cutting disc plays a crucial role in its performance and durability. Whether made from aluminum oxide, silicon carbide, or diamond particles, the material code within the IMPA system provides insight into the disc’s abrasiveness, heat resistance, and suitability for specific materials. Understanding these material codes enables procurement professionals to make informed decisions based on the requirements of their applications.

5. Packaging and Quantity:

Completing the IMPA code is information regarding packaging and quantity. This aspect ensures clarity regarding the unit of measurement (e.g., pieces, packs, or boxes) and the quantity supplied per package. Whether procuring cutting discs for a single project or stocking up for long-term usage, this component of the code streamlines the procurement process and minimizes ambiguity.

Significance of the Impact Code

Understanding the Impact Code is crucial for several reasons:

- Safety: The Impact Code provides vital information about the safe operating parameters of cutting discs. By adhering to these guidelines, users can minimize the risk of accidents and injuries in the workplace.

- Performance: Different materials require cutting discs with specific characteristics to achieve optimal results. By interpreting the Impact Code, users can select the right disc for the task at hand, ensuring efficient cutting and prolonging the disc’s lifespan.

- Compliance: In many industries, compliance with safety standards and regulations is mandatory. The Impact Code helps users identify cutting discs that meet or exceed these standards, ensuring legal compliance and peace of mind.

Conclusion:

Navigating the complexities of cutting disc procurement becomes more manageable with a thorough understanding of the IMPA code. By decoding its components and unraveling its significance, stakeholders can streamline the selection process, ensure compliance with specifications, and optimize resource allocation. As industries continue to evolve, the IMPA code remains a valuable tool for efficient and effective procurement practices in the maritime and beyond.