Cut-off wheels are essential tools in various industries, providing efficiency and precision for cutting a wide range of materials. Among these, the 3-inch cut-off wheel stands out for its compact size and versatility, making it a favorite for both professionals and DIY enthusiasts. In this blog, we’ll explore the benefits, applications, and tips for using 3-inch cut-off wheels effectively.

What is a 3-Inch Cut-Off Wheel?

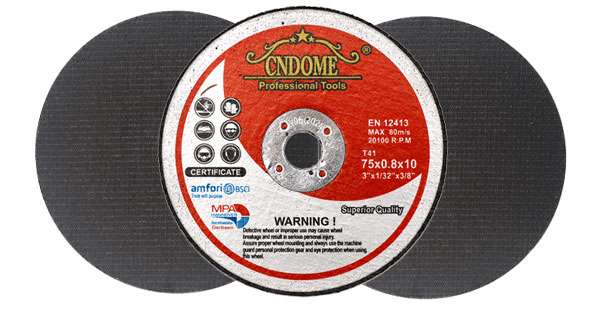

A 3-inch cut-off wheel is a thin, circular abrasive disc designed for cutting through various materials, including metal, plastic, wood, and masonry. Typically used with handheld grinders or mini cut-off tools, these wheels are ideal for tight spaces and detailed work, allowing users to achieve clean, precise cuts.

Advantages of Using 3-Inch Cut-Off Wheels

- Compact Size: The smaller diameter of the 3-inch wheel makes it perfect for working in confined areas where larger wheels cannot fit. This is especially useful for intricate jobs or when precision is crucial.

- Lightweight and Maneuverable: Weighing less than larger cut-off wheels, the 3-inch option is easy to handle, reducing fatigue during extended use. This makes it an excellent choice for professionals who work long hours or for hobbyists engaged in detailed projects.

- Versatile Applications: Whether you’re cutting metal pipes, sheet metal, plastic, or even tile, a 3-inch cut-off wheel can handle it all. Its adaptability makes it a valuable addition to any toolkit.

- Cost-Effective: Smaller wheels often come at a lower price point than their larger counterparts. This makes them an economical choice for users who need to replace their wheels frequently due to wear and tear.

Applications of 3-Inch Cut-Off Wheels

- Metal Fabrication: Ideal for cutting thin metal sheets, pipes, and rods, these wheels are commonly used in metalworking shops and by welders.

- Electrical Work: Electricians often use 3-inch cut-off wheels to cut conduit and other electrical materials safely and efficiently.

- Plumbing: When working with pipes and fittings, a 3-inch cut-off wheel provides precision without damaging surrounding materials.

- DIY Projects: For home improvement tasks like cutting tiles or removing rusted bolts, the 3-inch wheel offers the versatility needed for various projects.

Tips for Using 3-Inch Cut-Off Wheels

- Select the Right Wheel: Ensure you choose a wheel designed for the specific material you are cutting. For example, a diamond blade is suitable for tile, while an aluminum oxide wheel works well for metals.

- Safety First: Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask. Make sure the tool you’re using is compatible with the wheel size and type.

- Use a Steady Hand: Maintain a steady hand and consistent pressure when cutting. Let the wheel do the work; forcing it can lead to breakage or uneven cuts.

- Proper Speed Settings: Adjust the RPM settings of your grinder according to the wheel specifications to ensure optimal performance and prevent overheating.

- Regular Maintenance: Inspect your cut-off wheel for any signs of wear or damage before use. Regularly changing worn wheels not only enhances performance but also ensures safety.

Conclusion

The 3-inch cut-off wheel is a powerful tool that combines convenience and versatility, making it suitable for a wide array of cutting tasks. Whether you’re a professional tradesperson or a weekend DIYer, incorporating these wheels into your toolkit can significantly enhance your cutting capabilities. With proper use and maintenance, your 3-inch cut-off wheel will serve you well, delivering clean, precise cuts every time.