Cut-off wheels are essential tools for quickly and cleanly cutting through materials. While larger wheels are often chosen for heavy-duty jobs, 3-inch cut-off wheels provide a unique advantage in precision and control. In this article, we’ll dive into the versatility of 3-inch cut-off wheels, exploring their advantages, materials they work best with, and tips for getting the most out of these compact tools.

1. Why Choose a 3-Inch Cut-Off Wheel?

- Precision Cutting: Ideal for projects requiring fine, detailed cuts, a 3-inch wheel can navigate tight spaces where larger wheels might struggle.

- Portability: Smaller size means they fit on compact tools, perfect for on-the-go work or confined environments.

- High-Speed Efficiency: Their smaller diameter allows for high RPMs, translating to quicker, cleaner cuts in less time.

- Affordability: Due to their size, they often cost less than larger wheels, making them a cost-effective option for light to medium-duty tasks.

2. Applications of 3-Inch Cut-Off Wheels

- Metal Fabrication: From sheet metal to steel tubing, 3-inch cut-off wheels are commonly used in fabricating metal parts, particularly in automotive and manufacturing applications.

- Automotive Repair and Restoration: Compact tools with 3-inch wheels are great for tasks like exhaust repairs or cutting metal bodywork.

- Home DIY Projects: They offer the precision needed for small projects like cutting bolts, screws, and even plumbing pipes.

- Artistic Metalworking: Artists and crafters use these wheels for creating intricate metal pieces where detail and precision are key.

3. Types of Materials for 3-Inch Cut-Off Wheels

- Aluminum Oxide: Great for general-purpose metal cutting, particularly for iron, steel, and other ferrous metals.

- Silicon Carbide: Perfect for harder materials, like stone and ceramics, silicon carbide offers greater durability.

- Zirconia Alumina: This hybrid material is designed for cutting hard metals like stainless steel, providing a balance of strength and longevity.

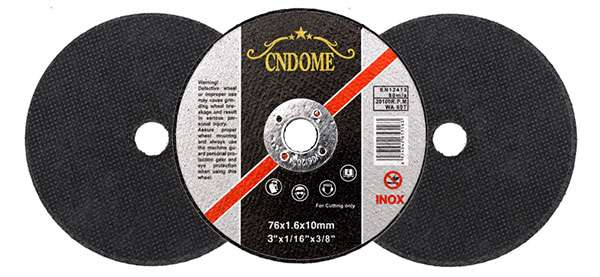

4. Key Features to Consider When Choosing a 3-Inch Cut-Off Wheel

- Thickness: Thinner wheels (around 1/32″) offer cleaner cuts with less resistance, ideal for fine work. Thicker options (up to 1/8″) provide more stability and durability for heavy cuts.

- Arbor Size: 3-inch cut-off wheels typically have a 3/8″ arbor, though there may be some variation. Ensure compatibility with your tool.

- Bonding Material: Resin-bonded wheels are common and offer a balance between durability and cutting speed. Always match the bonding strength to your material hardness for best results.

- Speed Rating: The RPM of the wheel should align with your tool’s output. 3-inch wheels can typically withstand higher speeds, making them compatible with high-RPM tools like die grinders and some angle grinders.

5. Tips for Safe and Effective Use of 3-Inch Cut-Off Wheels

- Always Wear Protective Gear: Goggles, gloves, and a mask are essentials when cutting metal or other hard materials.

- Proper Tool Handling: Keep a steady hand and follow the cut path without forcing the wheel, which can prevent breakage and improve accuracy.

- Maintain Correct Speed: Overloading or underpowering the wheel can lead to chipping or uneven cuts. Adjust your tool’s speed to match the wheel’s rating.

- Inspect Regularly: Check for cracks or wear on the wheel before use, as smaller wheels can be more susceptible to breakage under strain.

6. Maximizing the Lifespan of Your 3-Inch Cut-Off Wheel

- Avoid Overheating: Cutting too fast can generate excessive heat, reducing the wheel’s lifespan. Short, controlled cuts help prevent this.

- Storage Matters: Keep wheels in a dry, cool place to avoid moisture damage, which can weaken the bond and reduce durability.

- Use Appropriate Pressure: Applying the right amount of pressure maintains cutting efficiency and prevents premature wear.

Conclusion

3-inch cut-off wheels are small but mighty, bringing precision and versatility to a wide range of cutting applications. Whether you’re a professional or a DIY enthusiast, the 3-inch cut-off wheel offers a convenient solution for making detailed cuts. Just remember to choose the right material and thickness for your project, and follow safety guidelines to ensure a smooth, efficient, and safe cutting experience.