Abrasive cut-off disks are vital tools for a wide range of industries, including construction, automotive, metalworking, and DIY projects. Whether you’re cutting metal, steel, pipes, or tiles, these disks ensure precision, speed, and efficiency. But what exactly are abrasive cut-off disks, and why are they so popular? Let’s dive into their key features and benefits.

What Are Abrasive Cut-Off Disks?

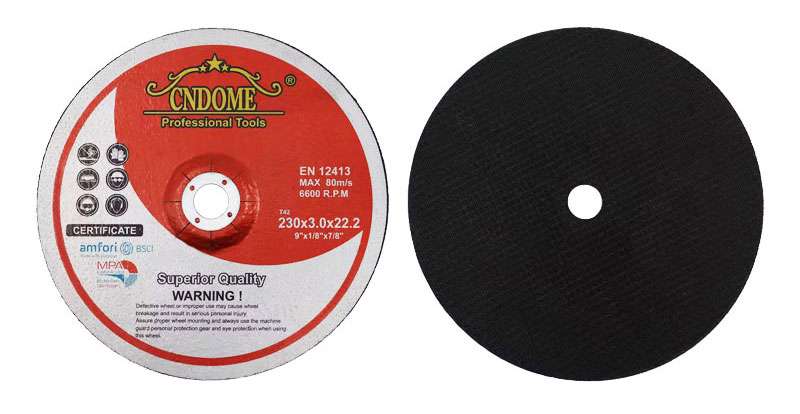

Abrasive cut-off disks (also known as cutting wheels or grinding wheels) are circular, thin abrasive tools used for slicing through materials. They are typically made of tough, durable materials like aluminum oxide, silicon carbide, or diamond abrasives. The disks are mounted on cutting machines, such as angle grinders or chop saws, and are engineered to withstand the high rotational speeds needed for cutting.

Key Features of Abrasive Cut-Off Disks

- Material Compatibility: Abrasive cut-off disks are designed for cutting a variety of materials, including:

- Metal (steel, stainless steel, cast iron)

- Concrete and stone

- Plastics and composites

- Tiles, ceramics, and more.

- Durability and Strength: These disks are made to endure intense friction, ensuring longevity during high-speed cutting operations. The abrasive grains are bonded firmly, allowing for effective cutting and a smooth finish.

- Precision: The thin nature of these disks ensures minimal material loss, and they provide a clean, straight cut, which is especially important in industries where precision is crucial.

- Variety of Sizes: Available in different diameters (ranging from 3 inches to 14 inches or more), abrasive cut-off disks can be chosen to fit specific cutting needs, from small precision work to large-scale cutting operations.

Benefits of Using Abrasive Cut-Off Disks

- Efficient and Fast Cutting: The aggressive abrasive particles on the disk’s surface ensure quick cutting through even tough materials, reducing downtime and increasing productivity.

- Versatility: With the right disk, users can cut through a range of materials. This makes them suitable for various tasks, including industrial applications and home projects.

- Cost-Effective: While the initial investment in the right abrasive cut-off disks might seem high, the long-lasting nature of the product makes it a cost-effective solution for professionals and DIYers alike.

- Ease of Use: These disks are simple to mount on a grinder or saw, making them easy to use for both seasoned professionals and novice users. They require minimal maintenance, which further adds to their convenience.

- Safety: Modern abrasive cut-off disks are designed with safety in mind, featuring reinforced structures to minimize the risk of breakage. However, proper handling and protective gear are essential to ensure safety during use.

How to Choose the Right Abrasive Cut-Off Disk

Choosing the correct abrasive cut-off disk for your job depends on several factors:

- Material Being Cut: Different abrasives work better for different materials. For example, aluminum oxide works well on steel, while silicon carbide is often used for cutting concrete and other hard materials.

- Thickness of the Material: Thicker materials require a more durable, often larger, cutting disk.

- Cutting Speed: If speed is essential, look for a disk designed for faster cutting to improve efficiency.

- Machine Compatibility: Ensure that the disk you choose is compatible with the type of cutting tool you’re using.

Safety Tips for Using Abrasive Cut-Off Discs

Safety is paramount when working with abrasive cut-off disks. Always:

- Wear appropriate personal protective equipment (PPE), such as safety goggles, gloves, and hearing protection.

- Ensure the disk is properly mounted and securely fastened.

- Use the correct RPM speed as recommended by the manufacturer to avoid accidents.

- Keep the work area clear and avoid distractions while cutting.

- Inspect the disk before use for signs of damage or wear, and replace any disks that appear compromised.

Conclusion

Abrasive cut-off disks are indispensable in a wide range of industries for their durability, speed, and versatility. They provide clean, precise cuts in tough materials, making them essential for professionals and DIY enthusiasts alike. By choosing the right disk and following safety practices, you can ensure successful, efficient cutting on every job.

Have you ever used abrasive cut-off discs? What materials do you typically cut with them? Let us know your experiences in the comments!