Small angle grinders are versatile power tools that have become indispensable in various industries and DIY projects. One key element that determines their effectiveness is the cutting blade they use. In this blog post, we will delve into the world of cutting blades for small angle grinders, exploring the types, materials, and applications that make them essential for a wide range of tasks.

Understanding the Basics: Types of Cutting Blades

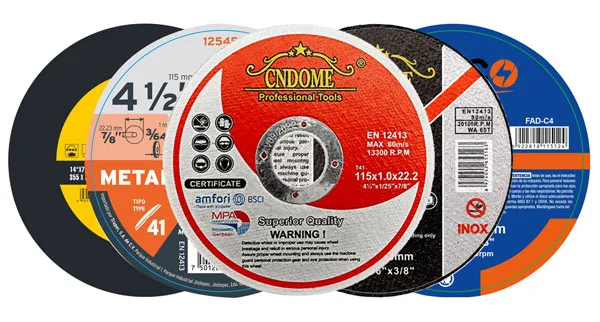

Small angle grinders can accommodate different types of cutting blades, each designed for specific tasks. Common types include abrasive wheels, diamond blades, and metal cutoff wheels. Abrasive wheels are ideal for cutting through metal, while diamond blades are excellent for hard materials like concrete, tile, and stone. Metal cutoff wheels, as the name suggests, are specifically designed for cutting through metal.

Materials Matter: Choosing the Right Blade Material

The material of the cutting blade plays a crucial role in its performance. For cutting through metal, aluminum oxide or silicon carbide abrasive wheels are popular choices. Diamond blades, featuring synthetic diamonds embedded in the blade’s edge, are perfect for cutting through hard materials like concrete and ceramic tiles. Always ensure that the chosen blade material aligns with the material you are working on to achieve the best results.

Size and Thickness: Finding the Right Dimensions

Cutting blades come in various sizes and thicknesses, and choosing the right dimensions is essential for optimal performance. Larger blades are suitable for heavy-duty tasks, while smaller ones offer precision in intricate cuts. Additionally, the thickness of the blade influences its durability and the quality of the cut. Thicker blades are more robust but may sacrifice some precision.

Safety First: Tips for Proper Usage

Safety should always be a priority when working with small angle grinders and cutting blades. Ensure that the grinder is properly secured, wear appropriate personal protective equipment, and follow the manufacturer’s guidelines. Regularly inspect the cutting blade for signs of wear and tear, and replace it promptly if necessary. Proper handling and maintenance contribute to both safety and the longevity of the cutting blade.

Applications Across Industries

Cutting blades for small angle grinders find applications across various industries. From construction and metalworking to woodworking and masonry, these blades are versatile tools that can handle a wide range of materials. Understanding the specific requirements of your project will help you choose the right cutting blade for the job.

The Future of Cutting Technology

As technology advances, so does the world of cutting blades. Innovations in blade design and materials continue to improve efficiency, durability, and precision. Stay informed about the latest developments in cutting technology to ensure you have access to the best tools for your projects.

Conclusion:

Investing time in understanding the nuances of cutting blades for small angle grinders is crucial for achieving optimal results in your projects. Whether you’re a professional tradesperson or a DIY enthusiast, choosing the right blade for the job can make a significant difference in both efficiency and the quality of your work. So, equip yourself with the knowledge needed to unleash the true power of your small angle grinder.