Welcome to the cutting edge of metalworking! In this blog post, we’ll delve into the fascinating world of steel & metal cutting discs. These essential tools are the unsung heroes behind precise cuts, smooth finishes, and the transformation of raw materials into works of art. Join us as we explore the features, benefits, and tips for optimizing your metal-cutting endeavors.

Section 1: Understanding Steel and Metal Cutting Discs

1.1 What Are Cutting Discs?

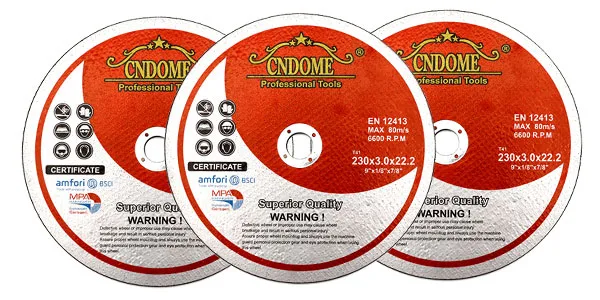

Metal cutting discs, also known as abrasive discs or cutting wheels, are indispensable tools designed for slicing through various metals with precision. Composed of abrasive grains bonded together, these discs are engineered to deliver efficient cuts while maintaining durability.

1.2 Types of Cutting Discs

Bonded Abrasives: Reinforced with a resin or a combination of resin and fiberglass, bonded abrasives are ideal for heavy-duty applications.

Coated Abrasives: Featuring abrasive grains attached to a flexible backing, coated abrasives offer versatility and are suitable for both large surfaces and intricate cuts.

Section 2: Choosing the Right Cutting Disc

2.1 Material Compatibility

Different metals require different cutting discs. Ensure the disc you choose is suitable for the specific material you are working with, whether it’s steel, aluminum, or other alloys.

2.2 Disc Size and Thickness

Selecting the right size and thickness is crucial for optimal performance. Larger discs are suitable for bigger cuts, while thinner discs are ideal for finer, more intricate work.

Section 3: Best Practices for Cutting Efficiency

3.1 Safety First

Prioritize safety by wearing appropriate protective gear, including safety glasses and gloves. Ensure your workspace is well-ventilated, and follow all manufacturer guidelines.

3.2 Proper Technique

Mastering the art of cutting involves using the right angle and applying consistent pressure. Allow the disc to do the work, and avoid forcing it through the material.

Section 4: Extending Cutting Disc Lifespan

4.1 Storage Tips

Store cutting discs in a dry and cool environment to prevent moisture damage. Keep them away from direct sunlight and extreme temperatures.

4.2 Maintenance

Regularly inspect discs for damage or wear. Replace worn-out discs promptly to maintain cutting precision and prevent accidents.

Conclusion:

Steel and metal cutting discs are indispensable tools for any metalworking enthusiast or professional. By understanding their types, choosing the right disc for the job, and following best practices, you can unlock the full potential of these tools, achieving clean cuts and impeccable finishes in your metalworking projects. Happy cutting!