When it comes to selecting the right cutting disc for your project, understanding the various thicknesses available can make a significant difference in the efficiency and quality of your work. This is particularly true for 230mm (9-inch) cutting discs, which are commonly used in a range of applications from metalworking to construction. In this blog, we’ll explore the different thicknesses of 230mm cutting discs, their applications, and how to choose the right one for your needs.

Understanding Cutting Disc Thickness

Cutting disc thickness directly influences the performance and suitability of the disc for certain tasks. Thinner discs generally cut faster and produce less heat, while thicker discs offer greater durability and stability. The most common thicknesses for 230mm cutting discs are:

- 1.6mm

- 2.5mm

- 3.2mm

Each thickness has its own unique benefits and ideal use cases.

1.6mm Thickness: Speed and Precision

Ideal For: Thin metal sheets, stainless steel, and precision cutting.

Advantages:

- Versatility: Balances speed and durability, making it suitable for a wide range of applications.

- Improved Stability: Offers better stability compared to 1.6mm discs, reducing the risk of breakage.

- Good Performance: Provides a good mix of cutting speed and longevity.

Considerations:

- Moderate Heat: Generates more heat than 1.6mm discs, which can be a concern for heat-sensitive materials.

- Material Loss: More material is removed compared to thinner discs, though it remains efficient.

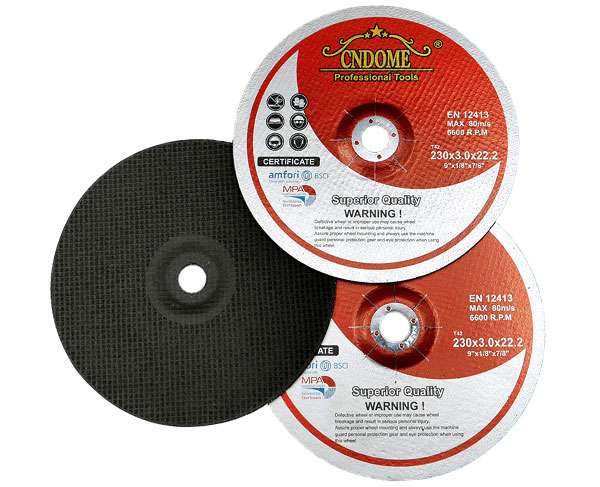

3.2mm Thickness: Durability and Strength

Ideal For: Thick metal sections, construction materials, and heavy-duty cutting.

Advantages:

- Durability: The thicker profile ensures a longer lifespan, even under rigorous use.

- Stability: Offers the highest level of stability, reducing the risk of disc breakage and improving user safety.

- Heavy-Duty Performance: Capable of cutting through thicker and tougher materials with ease.

Considerations:

- Slower Cutting Speed: The increased thickness slows down the cutting process.

- Higher Heat Generation: More friction leads to higher heat production, which can affect the material being cut and the disc itself.

Choosing the Right Thickness for Your Project

When selecting the appropriate 230mm cutting disc thickness, consider the following factors:

- Material Type: For thin or delicate materials, a 1.6mm disc is ideal. For general-purpose use, a 2.5mm disc offers a good balance. For thick or heavy-duty materials, opt for a 3.2mm disc.

- Cutting Speed: If speed is a priority, thinner discs will perform better.

- Durability Needs: For longer-lasting discs under heavy use, thicker discs are preferable.

- Heat Sensitivity: Thinner discs produce less heat, making them suitable for heat-sensitive materials.

Conclusion

Understanding the different thicknesses of 230mm cutting discs is crucial for selecting the right tool for your project. Whether you need speed, precision, or durability, there’s a disc thickness that meets your needs. By considering the material, cutting speed, durability, and heat sensitivity, you can make an informed choice that enhances your work efficiency and quality.

Investing in the right cutting disc not only improves your work outcomes but also ensures safety and cost-effectiveness in the long run. Choose wisely, and your cutting tasks will become smoother and more efficient than ever.