Bench and pedestal grinding wheels are essential tools in metalworking, woodworking, and maintenance shops. They are versatile, efficient, and indispensable for tasks like shaping, sharpening, and finishing materials. Whether you’re a professional or a DIY enthusiast, understanding the nuances of these grinding wheels can help you achieve optimal results.

What Are Bench and Pedestal Grinding Wheels?

Bench and pedestal grinding wheels are abrasive wheels mounted on a bench grinder or pedestal grinder. These machines are typically stationary and equipped with powerful motors to rotate the wheels at high speeds.

The wheels are used for tasks such as:

- Sharpening tools like chisels, drill bits, and cutting blades.

- Deburring edges of metal or woodwork.

- Grinding weld seams to ensure smooth finishes.

- Removing rust or paint from metal surfaces.

Types of Bench and Pedestal Grinding Wheels

Aluminum Oxide Wheels

Best for grinding high-tensile materials like steel and stainless steel.

Available in various grit sizes for coarse or fine grinding.

Silicon Carbide Wheels

Ideal for non-ferrous metals like brass, aluminum, and softer materials.

Also suitable for sharpening carbide-tipped tools.

Ceramic Grinding Wheels

Long-lasting and capable of handling heavy-duty applications.

Excellent for high-precision grinding.

Diamond Grinding Wheels

Perfect for sharpening carbide tools and cutting hard materials like glass and ceramics.

Often used in precision applications.

Wire Wheels

Designed for cleaning and polishing rather than grinding.

Useful for removing rust and preparing surfaces for painting.

Factors to Consider When Choosing a Grinding Wheel

Material Type

Choose the right wheel material for your specific task. For instance, aluminum oxide works best on steel, while silicon carbide is ideal for softer metals.

Grit Size

Coarse grits (36–60) for heavy material removal.

Fine grits (80–120) for finishing and polishing.

Wheel Size

Ensure the wheel size matches your grinder. Common sizes are 6-inch, 8-inch, or 10-inch diameters.

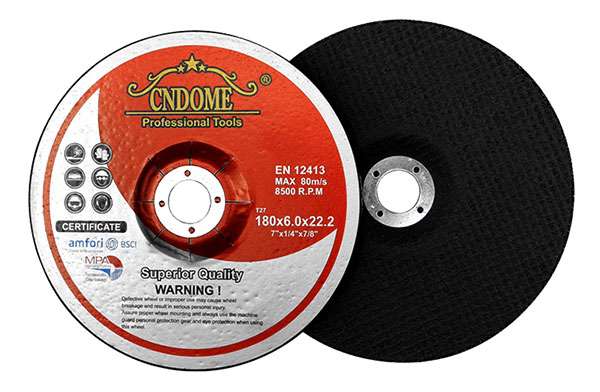

RPM Rating

Match the wheel’s RPM rating to your grinder’s speed to avoid damage or accidents.

Bond Type

Vitrified bonds for general-purpose grinding.

Resinoid bonds for faster cutting and precision grinding.

Proper Usage and Maintenance Tips

- Mounting: Ensure the wheel is properly mounted and secured to avoid wobbling. Always use the appropriate flanges.

- Dressing: Regularly dress the wheel using a dressing tool to maintain its shape and remove glazing.

Safety Precautions:

Always wear safety goggles and gloves.

Avoid grinding on the side of the wheel unless it is specifically designed for side grinding.

Use a tool rest to stabilize your workpiece.

Applications of Bench and Pedestal Grinding Wheels

Sharpening Tools

Keep chisels, axes, and knives razor-sharp for improved performance and safety.

Metal Fabrication

Grind, shape, and polish metals for welding, construction, or decorative purposes.

Surface Preparation

Remove rust, paint, and corrosion from metal surfaces for a clean finish.

Woodworking

Shape and smooth wooden pieces, preparing them for painting or assembly.

Advantages of Bench and Pedestal Grinding Wheels

- Durability: Made from high-quality abrasive materials to withstand rigorous use.

- Versatility: Suitable for a wide range of applications across different industries.

- Cost-Effectiveness: An affordable tool for professional and personal use.

Conclusion

Bench and pedestal grinding wheels are essential tools for any workshop. Selecting the right wheel for your grinder and maintaining it properly ensures efficient, precise, and safe grinding. Whether you’re sharpening tools, preparing surfaces, or grinding materials, these wheels can help you achieve excellent results with minimal effort.

Explore the variety of bench and pedestal grinding wheels available in the market and invest in a high-quality product tailored to your needs.