When it comes to cutting bolts efficiently and safely, the right tool makes all the difference. Cut-off wheels are indispensable for this task, offering precision, speed, and versatility. But with so many options available, how do you choose the best cut-off wheels for bolts for your needs? Let’s dive into the details.

Why Use Cut-Off Wheels for Bolts?

Cut-off wheels are specifically designed for tasks requiring precision cuts on hard materials like bolts. Here’s why they stand out:

- Clean Cuts: They produce smooth, burr-free cuts, reducing the need for additional finishing.

- Speed and Efficiency: Cut-off wheels work quickly, saving time in demanding tasks.

- Versatility: Compatible with various materials like steel, stainless steel, and other metals.

Key Factors to Consider

- Material Compatibility

The composition of the bolt determines the ideal cut-off wheel.- For Steel Bolts: Aluminum oxide wheels offer durability and excellent performance.

- For Stainless Steel Bolts: Opt for wheels with an inox (iron-free) composition to prevent contamination.

- For Hardened Bolts: Use high-performance wheels with advanced abrasives like zirconia or ceramic grains.

- Wheel Diameter

- For small bolts, a 3- to 4.5-inch wheel on a compact grinder works well.

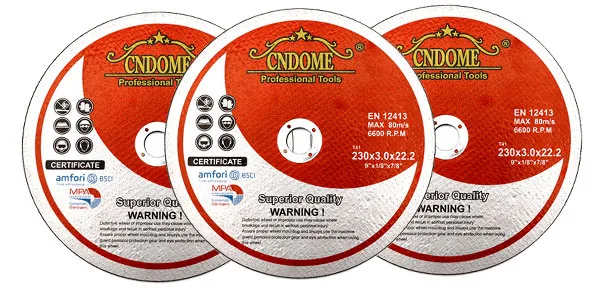

- For larger bolts, a 7- to 9-inch wheel ensures deeper cuts.

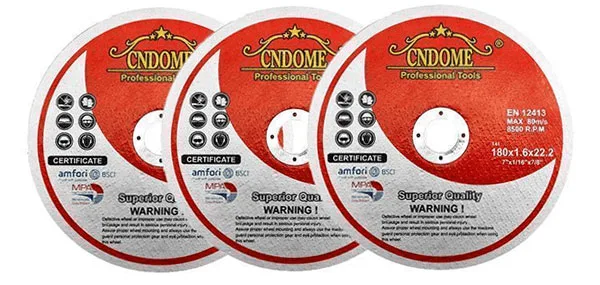

- Wheel Thickness

- Thinner wheels (1mm-1.6mm) provide precision and reduce heat generation.

- Thicker wheels (2mm-3mm) are more durable for heavy-duty tasks.

- Speed Rating

Ensure the wheel’s RPM rating matches or exceeds your grinder’s RPM to avoid accidents and ensure optimal performance. - Bond Type

- Resin-Bonded Wheels: Popular for their balance of strength and flexibility, ideal for cutting bolts.

- Reinforced Wheels: Provide added durability for heavy-duty applications.

Best Practices for Using Cut-Off Wheels

- Safety First

- Wear protective gear: safety glasses, gloves, and ear protection.

- Ensure the workpiece is securely clamped to avoid movement during cutting.

- Use the Right Grinder

- Choose an angle grinder that matches the wheel’s specifications.

- Maintain consistent pressure for a smooth cut without overloading the tool.

- Avoid Overheating

- Overheating can weaken the bolt or affect the cut-off wheel’s performance.

- Use intermittent cutting techniques to manage heat.

- Regular Inspection

- Check the wheel for cracks or wear before use.

- Replace worn-out wheels to maintain efficiency and safety.

Popular Options for Cut-Off Wheels for Bolts

- 4.5-Inch Metal Cutting Discs

- Ideal for general-purpose bolt cutting.

- Commonly made of aluminum oxide.

- Inox Cut-Off Wheels

- Perfect for stainless steel bolts.

- Prevents material contamination.

- Mini Cutting Discs

- Great for precision cutting in tight spaces.

- Heavy-Duty 7- or 9-Inch Wheels

- Suitable for industrial applications and larger bolts.

Conclusion

Cutting bolts with precision and efficiency depends on choosing the right cut-off wheels and following best practices. By considering factors like material compatibility, wheel thickness, and grinder specifications, you can ensure clean and safe cuts every time. Whether you’re a DIY enthusiast or a professional, investing in high-quality cut-off wheels tailored to your needs will save time and deliver outstanding results.

Need help selecting the perfect cut-off wheel for your bolt-cutting project? Let us know—we’re here to guide you!