When working with carbon steel, whether for industrial projects, construction, or DIY tasks, selecting the appropriate cutting disc is crucial for achieving optimal results. Carbon steel, known for its strength and durability, presents unique challenges when it comes to cutting. Understanding the characteristics of cutting discs and how they interact with carbon steel can make a significant difference in performance and safety.

Understanding Carbon Steel

Carbon steel is an alloy of iron and carbon, and it can have varying levels of carbon content, which affects its hardness and strength. The three main types of carbon steel are low carbon steel, medium carbon steel, and high carbon steel. Each type has different properties and requires specific approaches for cutting.

Types of Cutting Discs

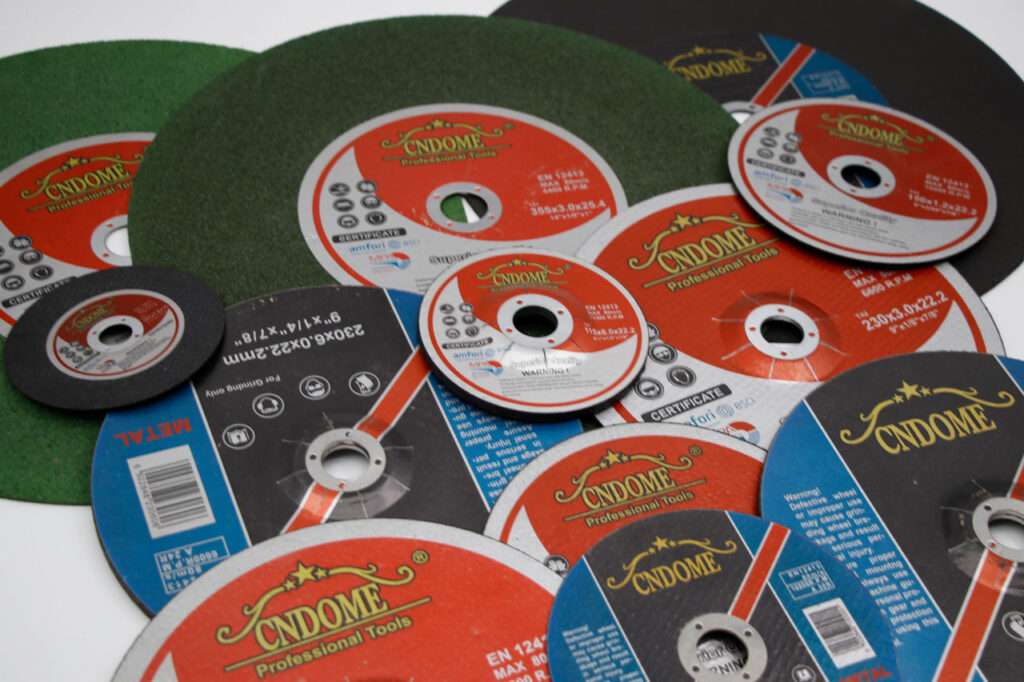

There are several types of cutting discs available, each suited for different materials and applications:

- Abrasive Cutting Discs: These are the most common type and are typically made from aluminum oxide or silicon carbide. They are designed to cut through metals by grinding away material. For carbon steel, aluminum oxide discs are often preferred due to their durability and effectiveness.

- Diamond Cutting Discs: These discs are embedded with industrial diamonds and are used for more demanding cutting tasks. While they are more expensive, they offer superior performance and longevity, especially for high-carbon steels.

- Flap Discs: Though more commonly used for grinding and finishing, some flap discs are designed to cut metal. They offer a smoother cut and are useful for tasks requiring precision and reduced heat generation.

Choosing the Right Disc

When selecting a cutting disc for carbon steel, consider the following factors:

- Disc Material: For cutting carbon steel, look for discs made from aluminum oxide. They are designed to handle the hardness of carbon steel and provide a clean cut.

- Disc Size and Thickness: The size and thickness of the disc affect its cutting performance. Thicker discs are more durable but can be slower and generate more heat. Thinner discs cut faster and with less heat but may wear out quicker.

- Grain Size: The grain size of the cutting disc affects its cutting ability and finish. Finer grains provide a smoother cut but may take longer, while coarser grains cut more quickly but can produce a rougher finish.

- Speed Ratings: Ensure that the cutting disc’s speed rating matches or exceeds the operating speed of your tool. Using a disc with a lower speed rating can be dangerous and lead to disc failure.

Safety Considerations

Cutting discs can generate a lot of heat and sparks, so safety is paramount. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a face shield. Ensure the cutting area is clear of flammable materials, and follow the manufacturer’s instructions for safe use.

Maintenance and Care

Proper maintenance of cutting discs can prolong their lifespan and maintain cutting efficiency. Store discs in a dry, cool place, and avoid dropping or damaging them. Regularly check for signs of wear and replace discs that are cracked or worn out.

Conclusion

Selecting the right cutting disc for carbon steel involves understanding the material properties, disc types, and specific requirements of your cutting task. By choosing the appropriate disc and adhering to safety practices, you can achieve efficient and effective cutting results while ensuring your safety and the longevity of your equipment.

Online Message

Minimum Order Quantity: 5,000 Pcs, 10 Pcs Free Samples.

Contact Us For More Information!

Tel/WhatsApp

+86 18796960868

DomeGrinding@hotmail.com

Address