What is a Cut-Off Disc?

A cut-off disc, also known as a cutting wheel, is a thin, abrasive disc designed to cut through various materials such as metal, stainless steel, aluminum, and even masonry. These discs are commonly used with angle grinders, die grinders, and stationary cut-off saws for fast and efficient cutting operations.

Types of Cut-Off Discs

Cut-off discs come in different types, each designed for specific applications:

1. Bonded Abrasive Cut-Off Discs

These discs are made from bonded abrasive grains, such as aluminum oxide or zirconia, and are reinforced with fiberglass for durability. They are ideal for cutting ferrous metals, stainless steel, and alloys.

2. Diamond Cut-Off Discs

Diamond discs feature a metal blade with industrial-grade diamond particles bonded to the edge. They are used for cutting hard materials like concrete, tiles, and stone.

3. Resin-Bonded Thin Cut-Off Discs

These are ultra-thin cutting discs designed for precise and fast cutting with minimal material loss. They are perfect for sheet metal, rebar, and thin-walled tubing.

Key Features to Consider When Choosing a Cut-Off Disc

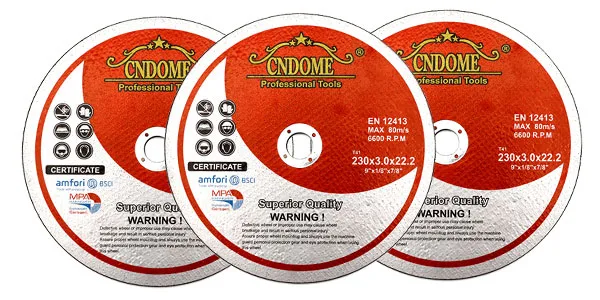

1. Disc Diameter and Thickness

- Common sizes: 3-inch, 4.5-inch, 7-inch, and 9-inch.

- Thin discs (1.0mm – 1.6mm): Ideal for fast and precise cuts with reduced burr formation.

- Thicker discs (2.5mm – 3.0mm): Provide more durability for cutting thicker materials.

2. Material Compatibility

Ensure the disc is designed for the material you’re cutting. Using the wrong disc can lead to inefficient cuts, excessive wear, and safety risks.

3. Maximum RPM Rating

Always match the disc’s RPM rating with your tool’s speed to avoid breakage and accidents.

4. Reinforcement

Some cut-off discs have fiberglass reinforcement for added strength, which is crucial when cutting tough materials like steel.

Best Practices for Using Cut-Off Discs Safely

- Wear proper PPE: Always use safety goggles, gloves, and a face shield.

- Check for damage: Inspect the disc for cracks before use.

- Use the right tool: Ensure the grinder or saw is compatible with the disc size and speed rating.

- Secure your workpiece: Prevent movement to maintain control during cutting.

- Apply even pressure: Avoid excessive force, which can cause the disc to break.

Conclusion

Cut-off discs are essential tools for clean and efficient cutting across various materials. Selecting the right type, following safety practices, and using high-quality discs can enhance performance and longevity. Whether you’re working with metal, concrete, or tiles, having the right cut-off disc ensures precise and smooth cutting results.

Would you like a specific focus, such as a particular material or brand recommendation?