Cut-off wheels are a staple in metalworking and DIY projects, especially when it comes to cutting bolts with precision and efficiency. Whether you’re dealing with rusted bolts, oversized fasteners, or simply making custom-length bolts, the right cut-off wheel can make all the difference.

Why Use a Cut-Off Wheel for Cutting Bolts?

- Efficiency: Cut-off wheels are designed for fast, clean cuts. Compared to a hacksaw or other manual tools, they significantly reduce cutting time.

- Precision: A cut-off wheel can make sharp, accurate cuts, ensuring the bolt is the exact length you need.

- Versatility: These wheels work on a variety of bolt materials, including steel, stainless steel, and even alloy bolts.

- Convenience: With the right tools, cut-off wheels can be used in handheld grinders, benchtop machines, or specialized cutting equipment.

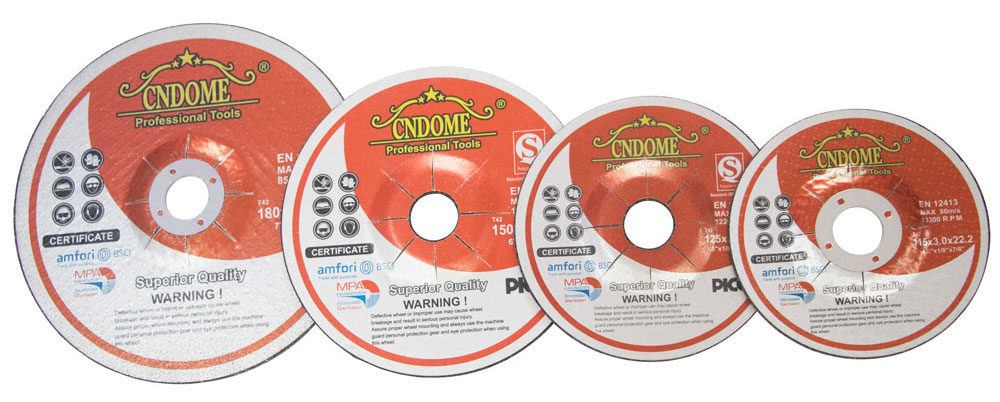

Types of Cut-Off Wheels for Bolts

Choosing the right cut-off wheel depends on the material of the bolt and the type of grinder you’re using.

- Metal-Specific Wheels: Designed for steel or stainless steel bolts, these are reinforced with aluminum oxide or zirconia for durability.

- Thin Cut-Off Wheels: Ideal for precision work, these wheels (1mm to 1.5mm thickness) produce minimal burrs and waste.

- Diamond Cut-Off Wheels: Perfect for hard or coated bolts, offering extended service life and superior cutting performance.

Tips for Cutting Bolts with Cut-Off Wheels

- Use the Right Equipment: Ensure your angle grinder or rotary tool is compatible with the cut-off wheel. Always check the size and arbor compatibility.

- Secure the Bolt: Clamp the bolt in a vise to prevent movement during cutting.

- Mark the Cut Line: Use a marker or tape to indicate where the cut will be made for precise results.

- Apply Consistent Pressure: Let the wheel do the work; avoid excessive force that could damage the wheel or cause uneven cuts.

- Wear Safety Gear: Protect your eyes, hands, and face with goggles, gloves, and a mask to guard against sparks and debris.

Applications of Cut-Off Wheels for Bolts

- Automotive Repairs: Cutting rusted or damaged bolts during vehicle maintenance.

- Construction: Trimming bolts to the correct size for structural applications.

- DIY Projects: Customizing furniture, repairing household items, or creating metal crafts.

- Industrial Maintenance: Removing oversized or stuck bolts in machinery.

Recommended Products

- 4-1/2” Thin Cut-Off Wheel: Ideal for handheld grinders, offering precision and durability.

- 3” Mini Cut-Off Wheel: Best for compact, detailed cutting tasks.

- Diamond Edge Cut-Off Wheel: Perfect for cutting through hardened or specialty bolts.

Maintaining Your Cut-Off Wheels

- Inspect wheels for cracks or damage before use.

- Store in a cool, dry place to prevent warping or moisture damage.

- Replace wheels when they become too small for safe operation or lose efficiency.

Cut-off wheels for bolts are indispensable for professionals and DIY enthusiasts alike. With the right wheel and proper technique, you can achieve clean, precise cuts every time, making your projects smoother and more efficient.

Are you ready to upgrade your toolset with high-quality cut-off wheels? Share your experiences or questions in the comments below!