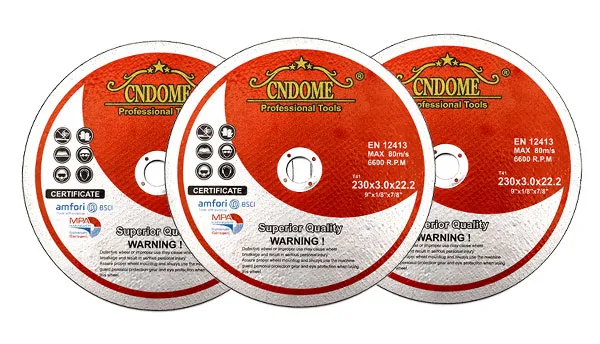

In the realm of cutting technology, innovation continues to push boundaries, and the rise of ultra-thin cutting discs has been a game-changer. These sleek and precision-engineered tools have revolutionized the cutting landscape, offering unmatched advantages for various industries and applications. Join us on this cutting-edge journey as we explore the wonders of ultra-thin cutting discs and the endless possibilities they bring to the world of cutting.

Precision Redefined:

At the heart of the ultra-thin cutting disc revolution lies the pinnacle of precision. These razor-thin discs are crafted with meticulous attention to detail, allowing for smooth, clean, and exact cuts. Whether it’s metal, ceramics, tiles, or other materials, the precision offered by ultra-thin cutting discs ensures that craftsmen and professionals achieve their desired results with unparalleled accuracy.

Maximum Efficiency:

The thinner the cutting disc, the less material it removes during each cut, leading to increased efficiency. Ultra-thin cutting discs significantly reduce material waste, making them a cost-effective choice for industries that require frequent cutting operations. The enhanced efficiency not only saves time but also lowers expenses, enabling businesses to streamline their processes and maximize productivity.

Minimal Heat and Reduced Friction:

One of the notable advantages of ultra-thin cutting discs is their ability to generate less heat during cutting. The reduced thickness and design result in lower friction, preventing overheating and minimizing the risk of damaging sensitive materials. This characteristic is particularly valuable in applications like cutting delicate metals, plastics, or composite materials, where precision and material integrity are crucial.

Versatility Unleashed:

Ultra-thin cutting discs are incredibly versatile, catering to a broad spectrum of cutting needs. From industrial manufacturing to DIY projects, these discs shine in every application. Their adaptability ensures that professionals can effortlessly tackle various materials and projects, saving time and investment in specialized cutting tools.

Portability and Ease of Use:

The slim profile of ultra-thin cutting diss makes them lightweight and easy to handle, providing the operator with improved maneuverability and control. The reduced weight translates into less fatigue during prolonged cutting sessions, allowing professionals to maintain focus and achieve exceptional results with greater ease.

Enhanced Safety:

The minimized thickness of these cutting discs contributes to safer operations. With reduced kickback potential, users can work with confidence, knowing that the risk of accidents is significantly diminished. Ultra-thin cutting discs adhere to the highest safety standards, making them a preferred choice for professionals seeking reliable cutting solutions.

Innovative Applications:

Ultra-thin cutting diss have opened the door to an array of innovative applications. From intricate artistic designs to thin grooves for advanced engineering components, these discs facilitate unprecedented levels of creativity and craftsmanship. The ability to create delicate, precise cuts has resulted in groundbreaking possibilities across diverse industries.

In the world of cutting technology, ultra-thin cutting discs stand as a testament to human ingenuity and progress. Their unmatched precision, efficiency, and versatility have redefined the art of cutting, empowering craftsmen and professionals alike to achieve extraordinary results. As innovation continues to shape the future of cutting, ultra-thin cutting discs will remain at the forefront of the industry, inspiring creativity, enhancing productivity, and ushering in a new era of precision cutting. Embrace the potential of ultra-thin cutting diss, and witness the cutting edge of tomorrow, today.