Steel pipe factories are at the forefront of industrial production, requiring precision, efficiency, and durability in every stage of their operations. Cutting wheels are essential tools in these facilities, enabling precise cuts, minimizing material waste, and ensuring smooth workflow. This blog will provide insights into selecting the best cutting wheels for steel pipe factories and highlight key factors that enhance performance and safety.

Understanding the Demands of Steel Pipe Cutting

Steel pipe manufacturing involves cutting through various grades of steel, including carbon steel, stainless steel, and alloy steel. These processes often demand:

- Consistency: Uniform cuts without deformation.

- Speed: High cutting efficiency to match production targets.

- Durability: Cutting tools that withstand high pressures and extended use.

Types of Cutting Wheels for Steel Pipes

Aluminum Oxide Cutting Wheels

- Ideal for cutting carbon steel pipes.

- Offers excellent durability and cost-effectiveness.

Zirconia Alumina Cutting Wheels

- Suitable for high-tensile steel pipes.

- Provides faster cutting speeds and longevity.

Diamond Cutting Wheels

- Best for precision cuts on stainless steel or alloy pipes.

- High durability but comes at a premium cost.

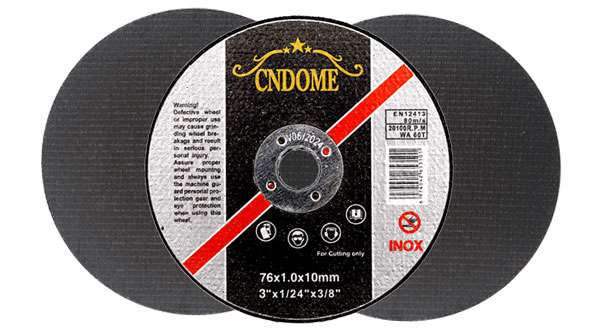

Resin-Bonded Thin Cutting Wheels

- Designed for minimal material loss.

- Excellent for clean and precise cuts.

Factors to Consider When Choosing Cutting Wheels

Material Compatibility

Match the cutting wheel material to the type of steel being processed.

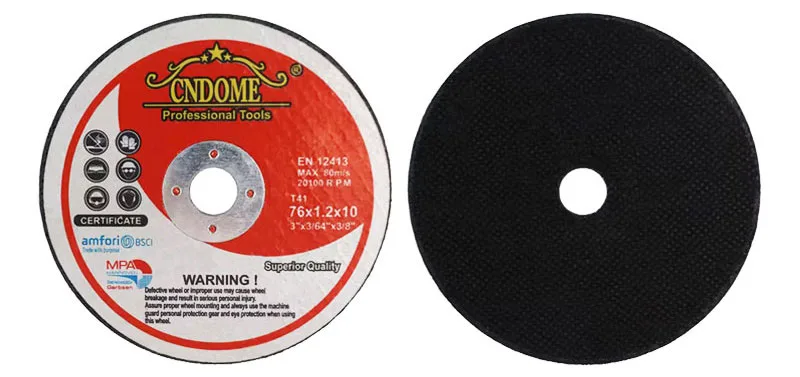

Size and Thickness

- Thinner wheels are ideal for precision but may wear out faster.

- Larger diameter wheels are better for high-volume operations.

Speed Rating

Ensure the wheel matches the RPM of the cutting equipment to prevent failures.

Safety Certifications

Look for certifications such as ISO or EN standards to guarantee safety and reliability.

Durability and Wear Rate

Invest in wheels with high wear resistance to reduce frequent replacements and downtime.

Tips for Efficient Cutting Operations in Steel Pipe Factories

Use Proper Equipment

Ensure the cutting machine is compatible with the chosen wheel type.

Regular Maintenance

Clean and inspect cutting tools regularly to prevent unexpected failures.

Follow Safety Protocols

Equip workers with safety gear, including goggles, gloves, and face shields.

Optimize Cutting Parameters

Adjust the cutting speed and pressure based on the wheel and material to extend tool life.

Top Brands and Suppliers

For steel pipe factories looking to source cutting wheels, consider reputable manufacturers specializing in industrial-grade products. Collaborating with a reliable supplier ensures access to high-quality tools tailored to factory requirements.

Conclusion

The choice of cutting wheels directly impacts productivity, cost-efficiency, and quality in steel pipe factories. By understanding material compatibility, operational demands, and safety measures, manufacturers can optimize their processes and achieve superior results. Whether it’s precision cutting or high-speed operations, selecting the right cutting wheel is a cornerstone of industrial success.

For more information on cutting wheels tailored to your factory’s needs, reach out to experts or explore OEM customization options to ensure you get the best tools for the job.

Would you like to expand on any particular section or include information about specific brands?