In the world of metalworking, the EN 12413 grinding wheel stands as a symbol of excellence, efficiency, and uncompromising quality. As an international standard for safety and performance, this grinding wheel has become the cornerstone of precision cutting, shaping, and smoothing across industries. Join us on this journey as we explore the remarkable features, applications, and unparalleled benefits of the EN 12413 grinding wheel, a true force to be reckoned with.

Setting the Gold Standard: Understanding EN 12413

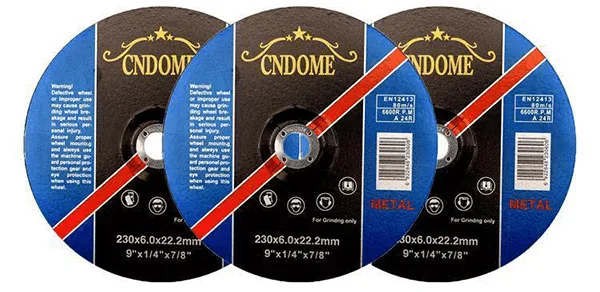

At the heart of the EN 12413 grinding disc lies a commitment to adherence to the highest safety and performance standards. Discover how this international norm ensures a grinding wheel’s quality, safety, and compatibility with various tools and machinery. From stringent testing methodologies to exhaustive quality checks, EN 12413 guarantees peace of mind for professionals and craftsmen worldwide.

Cutting-Edge Materials for Cutting-Edge Performance

Step into the world of advanced materials that make the EN 12413 grinding wheel a cut above the rest. Explore the spectrum of abrasive grains and bonding agents meticulously engineered to cater to diverse metalworking applications. Unravel the secrets behind the wheel’s resilience, efficiency, and durability, designed to withstand even the most demanding tasks.

Mastering Versatility: A Wheel for Every Application

The EN 12413 grinding wheel’s versatility knows no bounds. Uncover the diverse applications where this wheel excels, from precision machining in aerospace to shaping delicate surfaces in jewelry-making. Whether it’s ferrous metals, non-ferrous materials, or even stone and ceramics, this grinding wheel’s adaptability proves its worth across industries.

Embracing Efficiency: Reducing Downtime, Maximizing Output

Efficiency reigns supreme in the world of metalworking, and the EN 12413 grinding wheel ensures productivity like no other. Witness the grinding wheel’s ability to achieve fast stock removal, reduce downtime, and optimize machining processes. Say farewell to inefficiencies, and embrace a future where every minute counts towards exceptional output.

Safety First: Guarding the Workforce

A cornerstone of the EN 12413 standard is the unwavering commitment to safety. Unravel the design elements and safety features that protect professionals from potential hazards during grinding operations. Delve into the various safety recommendations and best practices that empower workers to unleash the grinding wheel’s power with confidence and peace of mind.

A Greener Tomorrow: Sustainable Grinding Practices

The EN 12413 grinding disc champions sustainability in metalworking. Explore the efforts made by manufacturers to create eco-friendly grinding solutions, reducing waste, and energy consumption. Discover how sustainability-conscious professionals can integrate the EN 12413 grinding wheel into their operations, aligning precision with environmental responsibility.

The EN 12413 grinding wheel epitomizes the epitome of grinding excellence. From its adherence to international safety and performance standards to the exceptional versatility and efficiency it offers, this grinding wheel has become the backbone of precision metalworking worldwide. As industries evolve and embrace sustainability, the EN 12413 grinding wheel stands ready to shape a greener, more efficient future for the metalworking world. Unlock the unrivaled grinding power of EN 12413, and witness the transformation of your metalworking operations into a symphony of precision and productivity.