Cut-off wheels are indispensable tools for cutting cast materials, offering precision and efficiency across various industrial and DIY applications. Cast materials such as cast iron, cast aluminum, and cast steel have unique properties that require specific tools to ensure clean cuts without compromising the material’s integrity. Here’s an in-depth look at what makes cut-off wheels ideal for these applications and how to choose the right one.

Understanding Cast Materials

- Cast Iron: Known for its hardness and brittleness, cast iron requires a cutting tool that minimizes heat and avoids cracking during operation.

- Cast Aluminum: A softer material prone to clogging abrasive tools, requiring cut-off wheels with anti-clogging features.

- Cast Steel: A tough material that demands durable and high-performance cutting discs for effective results.

Why Use Cut-Off Wheels for Cast Materials?

- Precision Cutting: Cut-off wheels provide accurate and clean cuts, essential for maintaining the dimensions and structural integrity of cast components.

- Efficiency: These wheels are designed to work quickly, reducing downtime during cutting operations.

- Versatility: Suitable for various cast materials, ensuring adaptability in different industries.

Key Features to Look for in Cut-Off Wheels for Cast Materials

- Abrasive Material

- Aluminum Oxide: Ideal for cutting cast iron and steel due to its toughness and durability.

- Silicon Carbide: Best for non-ferrous metals like cast aluminum, offering a smooth cut without clogging.

- Wheel Thickness

- Thin wheels (1-2 mm) are ideal for precision work and reduced material wastage.

- Thicker wheels provide durability for heavy-duty applications.

- Bonding Agent

- Resin-bonded wheels offer flexibility and resistance to heat buildup, which is critical when working with heat-sensitive cast materials.

- Reinforcement

- Fiberglass reinforcement ensures wheel stability, especially when working at high speeds.

Tips for Using Cut-Off Wheels on Cast Materials

- Select the Right Speed: Operating at the correct RPM prevents overheating and material damage.

- Use Proper Safety Gear: Always wear gloves, safety glasses, and protective clothing when using abrasive tools.

- Regular Inspection: Check wheels for cracks or damage before use to avoid accidents.

- Optimal Cutting Technique: Avoid excessive pressure; let the wheel do the work for a smoother cut.

Applications of Cut-Off Wheels for Cast Materials

- Automotive Industry

- Cutting cast iron engine blocks and cast aluminum parts.

- Construction

- Shaping cast steel reinforcements and pipes.

- Metal Fabrication

- Preparing cast components for welding or assembly.

Recommended Cut-Off Wheels for Cast Materials

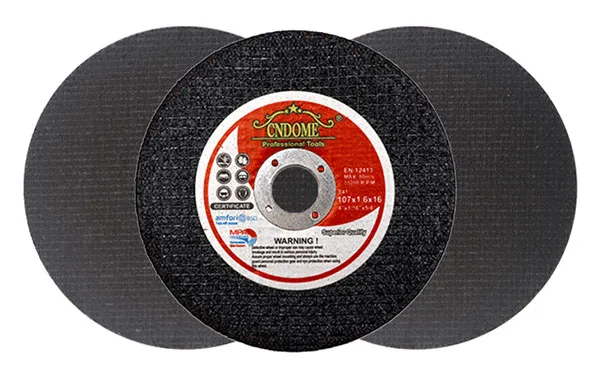

- CNDOME™ Cut-Off Wheels

- Features: High-performance aluminum oxide abrasive, reinforced fiberglass layers, and resin bonding.

- Best For: Cast iron and cast steel.

- Thin Metal Cutting Disc

- Features: Precision cutting for softer materials like cast aluminum.

- Best For: Non-ferrous cast components.

Conclusion

Cut-off wheels are essential for processing cast materials, offering precision, efficiency, and versatility. By understanding the unique requirements of each cast material and selecting the appropriate wheel, you can achieve superior results in your cutting operations.

Whether you’re in the automotive, construction, or metal fabrication industry, investing in high-quality cut-off wheels ensures optimal performance and safety.