In the realm of precision machining and metalworking, die grinders stand out as versatile tools cherished for their ability to tackle intricate tasks with finesse. These handheld powerhouses, equipped with high-speed rotating bits, are indispensable in shaping, smoothing, and polishing various materials. However, the efficacy and precision of die grinders heavily rely on the grinding wheels they employ. In this exploration, let’s delve into the world of grinding wheels tailored for die grinders and uncover their significance in machining processes.

Understanding Die Grinders: Precision in the Palm of Your Hand

Before delving into grinding wheels, let’s grasp the essence of die grinders. These compact yet potent tools are celebrated for their versatility and maneuverability. Whether in metalworking, woodworking, automotive, or fabrication industries, die grinders excel at intricate tasks, including deburring, shaping, grinding, and engraving.

Die grinders are designed for precision, offering operators the agility to access tight spaces and the control needed for delicate work. Their high rotational speeds, often exceeding 20,000 revolutions per minute (RPM), make them ideal for tasks requiring finesse and accuracy.

The Role of Grinding Wheels in Die Grinders

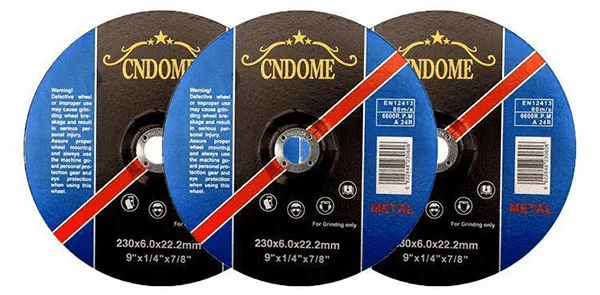

At the heart of every die grinder lies a grinding wheel, a critical component that dictates performance and functionality. Grinding wheels for die grinders come in a variety of shapes, sizes, and compositions, each tailored to specific tasks and materials. Whether it’s removing excess material, shaping contours, or achieving a smooth finish, the right grinding wheel is essential for optimal results.

Types of Grinding Wheels for Die Grinders

- Abrasive Wheels: These wheels feature abrasive particles bonded together, with popular materials including aluminum oxide, silicon carbide, and zirconia alumina. They excel at grinding, shaping, and smoothing various metals, plastics, and composites.

- Diamond Wheels: Diamond grinding wheels, embedded with industrial-grade diamonds, offer unparalleled hardness and durability. Ideal for precision grinding tasks, they effortlessly cut through hard materials such as carbide, ceramics, and glass.

- Mounted Points: These small, specialized grinding wheels are mounted on mandrels and are ideal for precise detail work. From deburring to shaping intricate contours, mounted points excel in tasks requiring precision and control.

Selecting the Right Grinding Wheel

Choosing the appropriate grinding wheel for a die grinder involves considering factors such as material composition, desired finish, and the specific task at hand. For instance, abrasive wheels with finer grit sizes deliver smoother finishes, while coarser grits excel at material removal.

Conclusion: Elevating Precision with Die Grinder Grinding Wheels

In the intricate world of precision machining, die grinders equipped with the right grinding wheels stand as indispensable allies. From shaping and smoothing to deburring and refining, these compact powerhouses wield unparalleled precision and control. By understanding the nuances of grinding wheel selection and their role in die grinder operations, craftsmen and artisans unlock new realms of possibility, ushering in a era of unparalleled precision and craftsmanship in the world of machining.

ioHcGfTD

iDhnTrOlwBqL