Indonesia, with its rapidly growing manufacturing and industrial sectors, has seen a significant demand for high-quality grinding wheels. As industries such as automotive, aerospace, construction, and metalworking continue to thrive, the need for reliable grinding wheel suppliers in Indonesia has never been greater. But with a multitude of suppliers to choose from, how can you ensure you’re partnering with the right one?

Here’s what to look for when searching for grinding wheel suppliers in Indonesia:

1. Quality Standards and Certifications

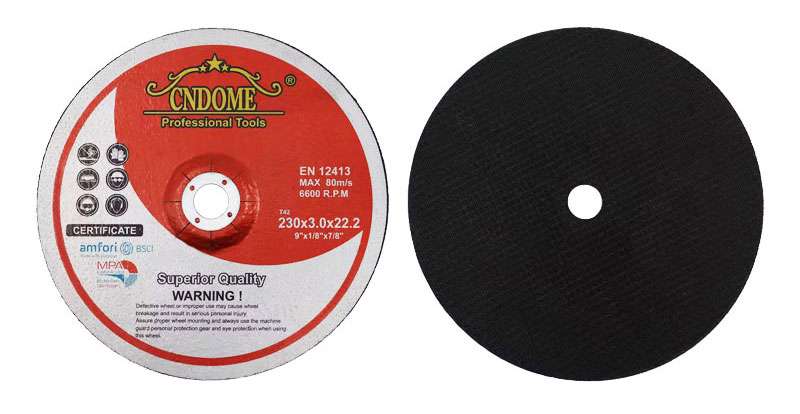

One of the first things to consider when choosing a supplier is the quality of their products. Grinding wheels are essential for high-precision operations, and you don’t want to compromise on quality. Ensure that the supplier adheres to international standards like ISO 9001, which guarantees that their products meet quality management systems.

Some grinding wheel suppliers in Indonesia may also offer specialized certifications for specific industries, such as aerospace, automotive, or construction. This is an added bonus if you require wheels for high-demand applications.

2. Range of Products

Grinding wheels come in many types, each suited for different applications. From surface grinding wheels to specialized grinding wheels for stainless steel or cast iron, your supplier should offer a wide variety of products to meet your needs. It’s also important to choose a supplier who can customize wheels to suit specific needs, whether it’s a certain size, shape, or abrasive material.

For example, suppliers that offer resin-bonded wheels for general-purpose grinding, as well as diamond or CBN (cubic boron nitride) wheels for more specialized cutting and grinding tasks, will give you more flexibility for your operations.

3. Strong Technical Support

Grinding wheels can be complex products, and you may need technical guidance on which wheel to choose based on your machinery, materials, and application. The best suppliers provide expert advice and technical support. They should be able to help you select the correct abrasive material, grain size, bonding agent, and wheel structure for your specific needs.

A supplier with a knowledgeable sales team and robust customer support is an invaluable asset. They can guide you through the proper maintenance and installation of your grinding wheels to ensure you get the best performance and longevity.

4. Fast Lead Times and Reliable Delivery

In an industry where downtime is costly, getting your grinding wheels delivered on time is essential. Look for a supplier in Indonesia who can provide quick lead times and reliable delivery. Some suppliers might even offer local stock to ensure faster turnaround times, which can significantly reduce downtime in your production process.

Additionally, choose suppliers who have a network of distributors across Indonesia. This will help ensure that you can quickly access replacement wheels or new products, no matter where your operation is located.

5. Competitive Pricing

While it’s essential not to sacrifice quality for cost, it’s still important to consider pricing when choosing a grinding wheel supplier. The market for grinding wheels in Indonesia is competitive, so suppliers will often offer a range of pricing options depending on the type of product and order volume.

Look for suppliers who offer bulk discounts, and ensure that their pricing structure aligns with your budget. Don’t forget to factor in shipping costs if you’re ordering from a supplier outside of your city or region.

6. After-Sales Service

A supplier that provides excellent after-sales service can help extend the life of your grinding wheels and improve your operations. This includes offering guidance on safe and effective wheel usage, providing wear and tear estimates, and helping with any issues that arise during use.

Some suppliers might even offer periodic maintenance services, where they inspect your grinding wheels and replace them if necessary, ensuring continuous optimal performance in your manufacturing processes.

7. Supplier Reputation

Finally, it’s essential to choose a supplier with a strong reputation for delivering quality products and excellent service. Read customer reviews, ask for references from other businesses in your industry, and check for any case studies or testimonials on their website. A well-established supplier with positive feedback from clients will typically provide more consistent results.

Key Suppliers in Indonesia:

- PT. Karya Jaya Abadi: Known for supplying high-quality grinding wheels and abrasives to industries in Indonesia, they offer a wide range of products and technical support.

- PT. Indah Jaya Abadi: Specializing in industrial abrasives, this company offers both off-the-shelf and customized grinding wheels for various applications.

- PT. United Grinding Indonesia: With a global reputation, they supply precision grinding wheels and abrasives, particularly for industries such as automotive and aerospace.

Conclusion

Finding a reliable grinding wheel supplier in Indonesia requires a balance of quality, product range, technical expertise, pricing, and customer service. By considering the factors above, you can ensure that your grinding operations run smoothly, efficiently, and cost-effectively. Whether you need a supplier for a one-time order or an ongoing partnership, investing time in choosing the right grinding wheel supplier will pay off in the long run.