Stainless steel is a popular material in various industries due to its corrosion resistance, strength, and aesthetic appeal. However, working with stainless steel requires specific tools to achieve the best results. One of the most essential tools for shaping, finishing, and polishing stainless steel is the grinding disc. In this blog, we’ll explore the types of grinding discs suitable for stainless steel, their features, and tips for selecting the right one for your project.

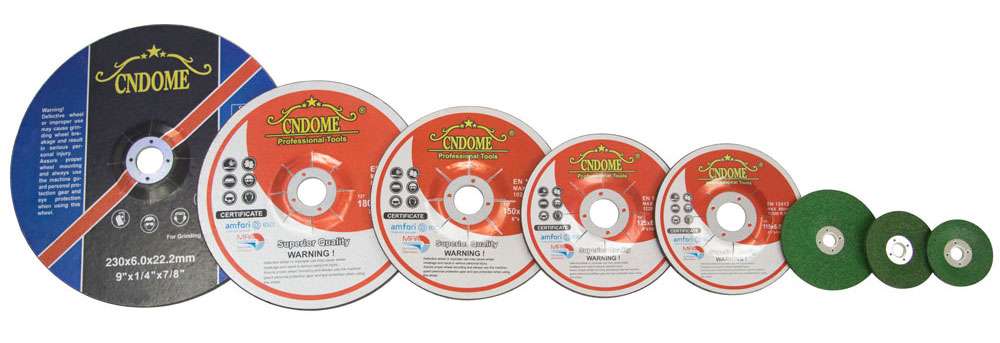

Types of Grinding Discs

- Zirconia Grinding Discs

- Application: Ideal for heavy grinding and stock removal.

- Features: Made with a blend of zirconia and aluminum oxide, these discs are durable and designed for aggressive material removal. They can withstand high temperatures and have a longer lifespan compared to other types.

- Aluminum Oxide Grinding Discs

- Application: Suitable for general-purpose grinding and finishing.

- Features: These discs offer good performance on stainless steel but may wear out more quickly than zirconia options. They are versatile and often used for less demanding tasks.

- Ceramic Grinding Discs

- Application: Best for heavy-duty grinding and applications requiring high performance.

- Features: Known for their exceptional durability and heat resistance, ceramic discs provide a high rate of material removal, making them a top choice for professional applications.

- Non-Woven Abrasive Discs

- Application: Excellent for surface finishing and blending.

- Features: These discs are made from a non-woven material infused with abrasive grains, allowing them to conform to the surface of the workpiece. They are perfect for achieving a polished finish without altering the metal’s structure.

Key Features to Consider

- Grit Size: The grit size of a grinding disc affects the finish of the material. Coarse grits (e.g., 36-60) are used for heavy stock removal, while finer grits (e.g., 80-120) are better for finishing and polishing.

- Disc Thickness: Thicker discs tend to be more durable and can withstand higher pressure, but they may not provide as fine a finish as thinner discs.

- Bonding Material: The bonding agent affects the disc’s performance. Resin-bonded discs are common for stainless steel applications due to their flexibility and heat resistance.

Tips for Choosing the Right Grinding Disc

- Assess the Application: Determine whether you need heavy stock removal, surface finishing, or a combination of both. This will help guide your choice of disc type and grit size.

- Check Compatibility: Ensure that the grinding disc is compatible with your angle grinder or other equipment. Consider the disc’s size, arbor hole, and RPM rating.

- Prioritize Quality: Invest in high-quality grinding discs. While they may be more expensive upfront, they often provide better performance and longer life, leading to cost savings in the long run.

- Follow Safety Guidelines: Always wear appropriate personal protective equipment (PPE) when grinding, including safety glasses, gloves, and hearing protection. Ensure that your workspace is well-ventilated and free of hazards.

Conclusion

Choosing the right grinding discs for stainless steel is crucial for achieving optimal results in your projects. By understanding the different types of discs available and considering key features and application needs, you can enhance your grinding efficiency and quality. Whether you’re a professional fabricator or a DIY enthusiast, selecting the right tool will ensure that your work shines—just like the stainless steel itself.