The thickness of a cutting disc plays a crucial role in determining its performance and suitability for different applications. Here are several key ways in which the thickness of a cutting disc affects its performance:

Cutting Speed:

The thickness of a cutting disc has a direct impact on its cutting speed. Thinner discs generally offer higher cutting speeds compared to thicker ones. This is because a thinner disc removes less material during each rotation, allowing for faster cutting. Thicker discs, on the other hand, require more material to be removed, resulting in a slower cutting process.

Durability:

Thicker cutting discs tend to be more durable and have a longer lifespan. They can withstand higher levels of stress and are less prone to bending or breaking. This makes them particularly suitable for heavy-duty cutting tasks or materials that require more force to cut through. Thicker discs are often used in industrial settings where robustness and longevity are essential.

Precision:

Thinner cutting discs offer better precision and accuracy during cutting operations. They produce narrower kerfs, which refers to the width of the cut. Thinner discs allow for more intricate and detailed cuts, making them ideal for applications where precision is crucial, such as in jewelry making or intricate metalwork. Thicker discs may result in wider cuts, leading to increased material loss.

Heat Dissipation:

During cutting, friction generates heat, which can potentially damage the cutting disc or the material being cut. Thinner cutting discs dissipate heat more effectively compared to thicker discs. The reduced thickness allows for better heat transfer, enabling the disc to stay cooler during cutting. This improved heat dissipation helps prevent overheating, which can lead to disc warping or premature wear. Thinner discs are particularly advantageous when working with heat-sensitive materials.

Vibration and Stability:

Thicker cutting discs tend to provide better stability and generate fewer vibrations during cutting operations. The increased thickness enhances the rigidity of the disc, reducing the likelihood of bending or flexing. This stability is particularly beneficial when cutting through hard or dense materials that require more force. It improves control over the cutting process and reduces the risk of accidents or damage to the workpiece.

Application Specificity:

Different cutting tasks require different disc thicknesses. Thin cutting discs, usually less than 1 millimeter in thickness, are commonly used for precision cutting applications. They excel in tasks that demand fine control and minimal material loss, such as cutting thin metal sheets, plastic, or delicate materials like glass or ceramics. Thicker cutting discs, ranging from 1 to 3 millimeters or more, are typically employed in heavy-duty applications. They are suitable for cutting thick metal, concrete, stone, and other robust materials that require higher cutting forces.

When selecting a cutting disc, it’s essential to consider the specific material to be cut, the required cutting speed, the level of precision needed, and the equipment being used. It is recommended to consult the manufacturer’s guidelines and recommendations to ensure optimal performance, safety, and longevity of the cutting disc.

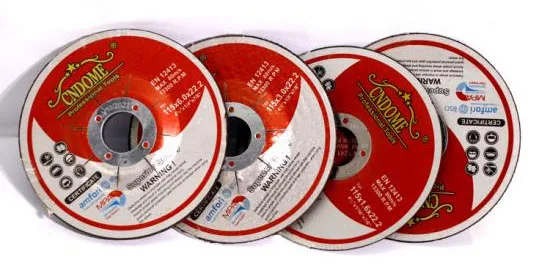

If you are interested in our cutting discs and grinding discs, welcome to contact us for free samples for quality testing, we will be your best choice.We look forward to further cooperation with customers all over the world.

WhatsAPP : +86 18796960868

Email : chris@czdome.com