In industrial settings, precision and efficiency are paramount. Among the essential tools in metalworking, industrial grinder metal cutting discs stand out as indispensable components. Whether you’re cutting through steel beams, aluminum sheets, or other metals, selecting the right cutting disc can make a significant difference in performance and productivity.

What Are Metal Cutting Discs?

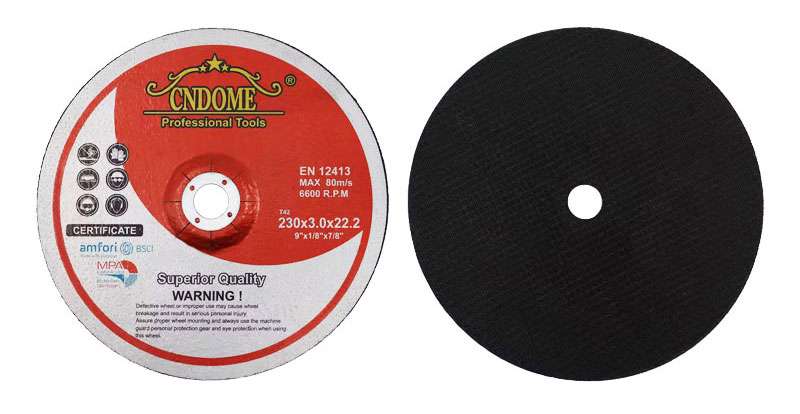

Metal cutting discs are abrasive tools designed for high-speed cutting of various metals. They are commonly used with angle grinders, stationary grinders, or other cutting machines in industries such as construction, automotive, and fabrication. These discs are crafted from abrasive grains bonded with resin to ensure durability and precise cutting.

Types of Metal Cutting Discs

Aluminum Oxide Discs

- Ideal for cutting ferrous metals like steel and cast iron.

- Known for durability and heat resistance.

Silicon Carbide Discs

- Best suited for non-ferrous metals like aluminum, copper, and brass.

- They deliver clean cuts with minimal material contamination.

Diamond Cutting Discs

- Designed for heavy-duty industrial applications.

- Offers exceptional longevity and precision, especially for hard metals.

Zirconia Alumina Discs

- Provides a balance of cutting speed and lifespan.

- Suitable for stainless steel and high-tensile alloys.

Key Features to Consider

Disc Size

- Standard sizes range from 4.5 inches to 9 inches for handheld grinders, while larger discs are used in stationary equipment.

Thickness

- Thinner discs (1mm to 1.6mm) are ideal for precision cuts.

- Thicker discs (2mm to 3mm) are better for heavy-duty applications.

Arbor Size

- Ensure the disc’s arbor matches the grinder for safe and efficient operation.

RPM Rating

- Always choose a disc that matches or exceeds the grinder’s RPM to avoid accidents.

Advantages of Using Quality Metal Cutting Discs

- Enhanced Efficiency: High-quality discs cut faster and more cleanly, reducing downtime.

- Longevity: Premium materials ensure longer tool life, lowering replacement costs.

- Safety: Durable discs minimize the risk of breakage during use.

- Versatility: Can handle a wide range of metals and applications.

Applications of Metal Cutting Discs

- Fabrication Shops: Cutting metal sheets, pipes, and rods for custom projects.

- Automotive Industry: Removing rusted bolts, cutting exhaust systems, or trimming body panels.

- Construction: Cutting rebar, beams, and structural steel on-site.

- Metal Recycling: Efficiently slicing through scrap metal for processing.

Safety Tips for Using Metal Cutting Discs

- Always wear appropriate PPE, including safety goggles, gloves, and ear protection.

- Inspect discs for cracks or damage before use.

- Ensure the grinder guard is in place and functioning correctly.

- Do not exceed the disc’s maximum RPM rating.

- Secure the workpiece to prevent movement during cutting.

Conclusion

Industrial grinder metal cutting discs are the backbone of many metalworking operations. By understanding the types, features, and applications of these tools, you can select the right disc for your specific needs. Investing in high-quality cutting discs not only enhances performance but also ensures safety and cost-effectiveness in the long run.

Whether you’re in construction, automotive, or manufacturing, the right metal cutting disc can transform the efficiency of your operations. Choose wisely, prioritize safety, and enjoy superior cutting results!

Would you like to explore specific brands, case studies, or advanced techniques for using metal cutting discs? Let me know!