Rotary tools are versatile instruments that have become essential in various DIY projects, crafts, and professional applications. One of the key accessories that enhance their cutting capabilities is the cutting disc. Whether you’re a seasoned craftsman or a DIY enthusiast, understanding the nuances of cutting discs for rotary tools can significantly impact the precision and efficiency of your work.

1. Types of Cutting Discs:

There’s a wide array of cutting discs available, each designed for specific materials and tasks. Common types include:

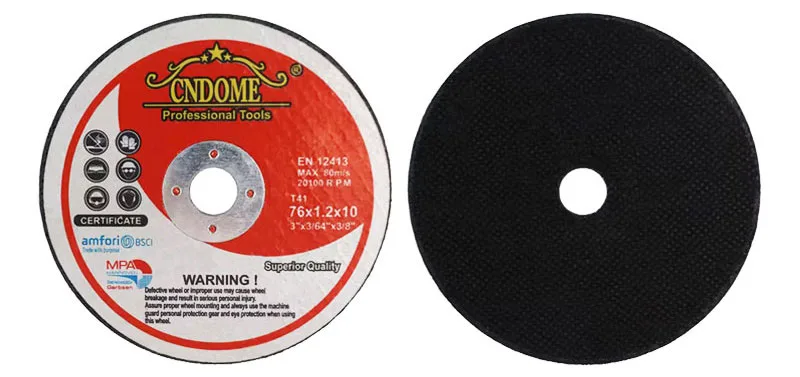

- Fiber Reinforced Discs: Ideal for cutting metals, these discs are reinforced with fiberglass for added strength and durability.

- Diamond Cutting Discs: Designed for cutting hard materials like tiles, ceramics, and glass, these discs are embedded with diamond particles.

- Abrasive Cutting Discs: Perfect for cutting through wood and softer materials, abrasive discs come in various grits for different levels of aggressiveness.

2. Choosing the Right Disc for the Job:

Selecting the appropriate cutting disc is crucial for achieving optimal results. Consider factors such as the material you’re working with, the required precision, and the rotary tool’s power. Using the wrong disc may lead to inefficiency, damage to the material, or even pose safety risks.

3. Safety First:

Before diving into your project, ensure that you have the necessary safety gear. This includes safety glasses, gloves, and hearing protection. Cutting discs operate at high speeds, generating sparks and debris, so taking precautions is essential.

4. Proper Installation:

Correct installation of the cutting disc is paramount for safety and efficiency. Ensure that the rotary tool is turned off and unplugged before attaching or changing discs. Follow the manufacturer’s instructions for installation, including securing the disc tightly and using any provided accessories, like mandrels or flanges.

5. Techniques for Precision Cutting:

Achieving precise cuts requires a steady hand and the right technique. Start with light pressure and let the cutting disc do the work. For straight cuts, guide the tool steadily along a marked line. For curves or intricate shapes, practice on scrap material first to get a feel for the tool’s maneuverability.

6. Maintaining Your Cutting Disc:

Regular maintenance is crucial for extending the life of your cutting discs. Keep an eye on wear and tear, and replace discs that show signs of damage or reduced cutting efficiency. Additionally, store your rotary tool and discs in a clean and dry environment to prevent corrosion.

7. Troubleshooting Common Issues:

If you encounter issues like overheating, wobbling, or excessive vibration, troubleshoot the problem before continuing. It could be due to improper installation, a worn-out disc, or issues with the rotary tool itself.

Conclusion:

Mastering the art of using cutting discs for rotary tools requires a combination of knowledge, skill, and attention to detail. By understanding the different types of discs, choosing the right one for your task, and following safety guidelines, you’ll unlock the full potential of your rotary tool and achieve precise and efficient cuts in your projects. So, gear up, stay safe, and let your creativity flourish with the precision of cutting discs in hand.