In the realm of manufacturing and craftsmanship, precision is paramount. Whether you’re shaping metals, sharpening blades, or honing intricate components, the quality of your tools can make or break your final product. Among these indispensable tools, grinding wheels stand as silent champions, tirelessly shaping, smoothing, and refining materials with unparalleled accuracy. In this guide, we delve into the intricate world of importing grinding wheels, exploring the nuances, considerations, and strategies essential for mastering precision in your craft.

Understanding Grinding Wheels: The Cornerstone of Precision

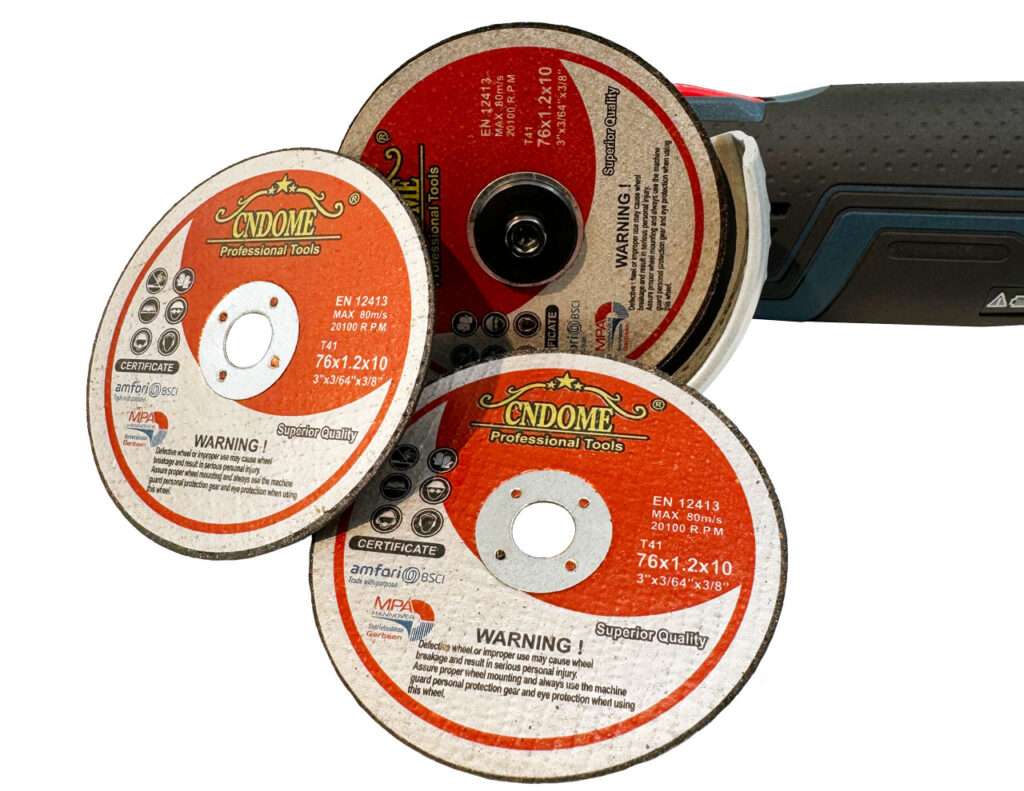

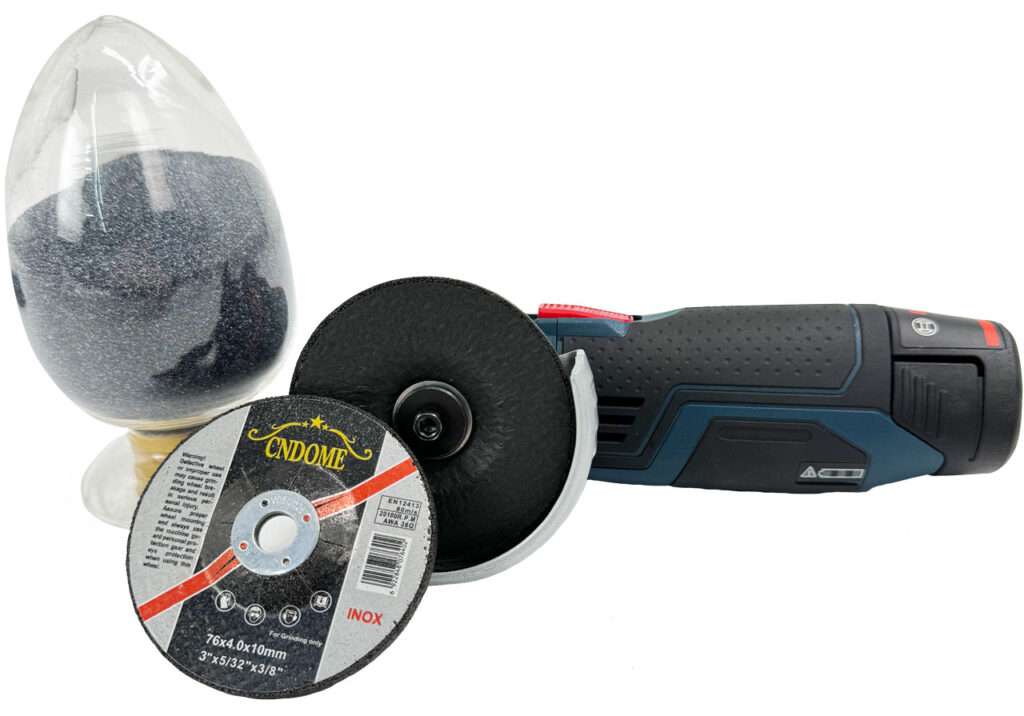

Grinding wheels, often composed of abrasive materials bonded together, serve as the workhorses of various industries. From aerospace engineering to culinary arts, these wheels come in diverse shapes, sizes, and compositions, tailored to specific tasks and materials. Silicon carbide, aluminum oxide, and ceramic grains are just a few examples of the abrasive materials employed, each offering unique properties suited for different applications.

Navigating the Import Landscape: Challenges and Opportunities

Importing grinding wheels involves navigating a labyrinth of regulations, suppliers, and logistical considerations. Understanding the regulatory landscape, including standards set by organizations like the ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration), is crucial for ensuring compliance and safety.

Identifying reputable suppliers is another critical step. Researching potential partners, scrutinizing product quality, and assessing manufacturing processes can help mitigate risks and ensure consistent performance. Additionally, fostering transparent communication and building long-term partnerships can lead to mutually beneficial collaborations and enhanced product development.

Tailoring Imports to Your Needs: Customization and Specialization

One size rarely fits all in the world of grinding wheels. Depending on your industry, materials, and applications, customization may be essential. Working closely with suppliers to tailor specifications such as grit size, bond type, and wheel geometry can optimize performance and efficiency, ultimately enhancing the precision of your operations.

Moreover, embracing specialization can unlock new possibilities and competitive advantages. Whether it’s investing in advanced abrasive technologies or leveraging novel bonding agents, staying abreast of industry trends and innovations can propel your craft to new heights of excellence.

Sustainability and Ethical Considerations: A Holistic Approach

In an era marked by heightened environmental awareness and ethical consciousness, sustainability is no longer an afterthought but a fundamental imperative. When importing grinding wheels, prioritizing suppliers committed to eco-friendly practices, ethical labor standards, and responsible sourcing can align your operations with broader societal values while safeguarding the planet for future generations.

Furthermore, adopting sustainable practices within your own operations, such as optimizing energy consumption and minimizing waste generation, reinforces your commitment to environmental stewardship and corporate social responsibility.

Conclusion: Precision Redefined

In the tapestry of precision engineering and craftsmanship, grinding wheels emerge as unsung heroes, epitomizing the marriage of artistry and technology. By mastering the intricacies of importing grinding wheels, you not only elevate the quality and precision of your creations but also embody a commitment to excellence that transcends boundaries.

As you embark on your journey, remember that precision is not merely a destination but a relentless pursuit—a quest for perfection woven into the very fabric of human endeavor.

So, sharpen your focus, refine your approach, and let the sparks of ingenuity illuminate your path toward mastery.

In this blog, I’ve tried to cover various aspects of importing grinding wheels, from understanding their importance to navigating challenges and embracing sustainability. If you need more detailed information on any specific aspect, feel free to let me know!