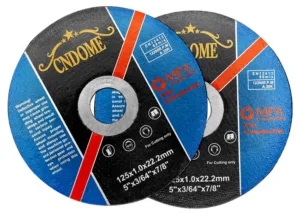

When it comes to precision in metalworking, the right tools can make all the difference. In this blog, we’ll explore the world of metal cutting discs, specifically focusing on the versatile 125mm variant. Get ready to unlock the secrets of efficient and accurate metal cutting.

Size Matters: Why 125mm?

Briefly explain the significance of the 125mm size, its balance between precision and versatility.

Highlight applications where this size excels, such as fabrication, welding, and general metalworking projects.

Cutting Edge Technology: Materials and Composition

Dive into the materials used in manufacturing 125mm metal cutting discs, emphasizing durability and heat resistance.

Discuss the importance of reinforced materials for longevity and safety during heavy-duty applications.

Versatility Unleashed: Types of Metals

Explore the range of metals that 125mm discs can handle – from mild steel to stainless steel.

Share insights on how the discs adapt to different metal compositions and thicknesses.

The Anatomy of Precision: Design Features

Break down the design elements that contribute to the precision of 125mm metal cutting discs.

Highlight features like thin kerfs for minimal material wastage and advanced tooth geometries for smoother cuts.

Safety First: Tips for Proper Usage

Offer practical tips for users, including proper mounting, using safety gear, and following recommended RPMs.

Emphasize the importance of regular inspections for wear and tear, ensuring optimal performance and safety.

Common Mistakes to Avoid

Discuss pitfalls users might encounter, such as improper technique, neglecting maintenance, or using the wrong disc for a specific application.

Provide solutions and guidance on how to avoid these mistakes for a seamless cutting experience.

Conclusion:

Equip yourself with the knowledge needed to master metal cutting discs125mm. Whether you’re a seasoned professional or a DIY enthusiast, understanding the intricacies of these tools will undoubtedly elevate your metalworking game. Stay sharp, stay precise!